Customised

profile wrapping

solutions

At Duespohl, you will find customised solutions to optimise your PVC or wood profile wrapping process. Discover efficient lines configurated to perfectly meet your requirements as well as retrofit components to update your existing machine.

Our technically competent Sales Engineers will be happy to give you advice on your process.

I would like to know more.

Contact us and your Sales Engineer will get back to you immediately.

Duespohl Highlights

-

high quality standard components

-

many smart optional components for all applications

-

patented slot nozzle for homogeneous application of only freshly melted glue

-

line including premelter and glue application system

-

degree of automation can be customised

-

many automated solutions to become independent from skills shortage

-

solutions to reduce downtimes and time required for set-up

-

retrofits to optimise your existing line

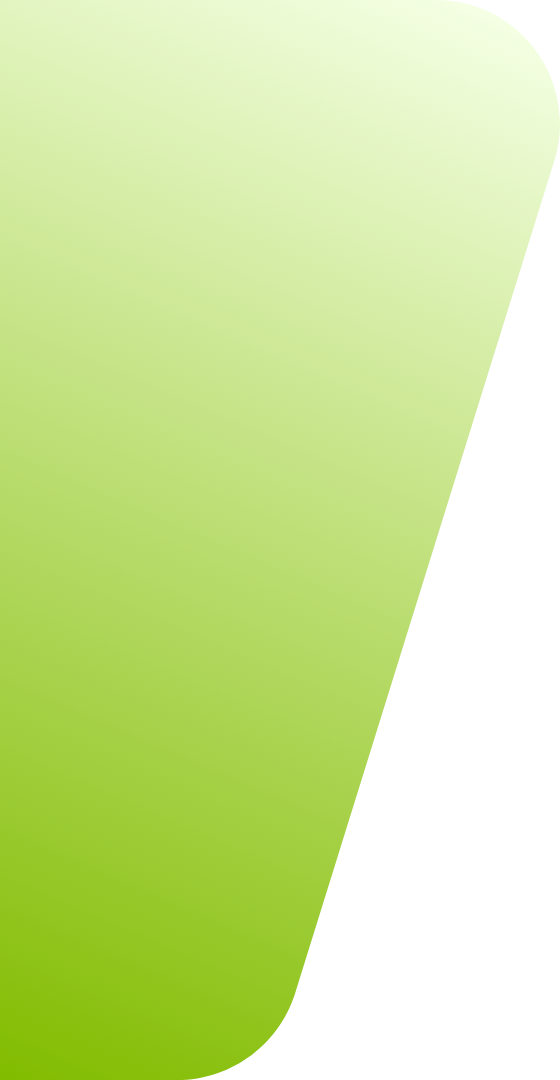

High performing line for work pieces made from wood (composites)

Example of a configuration of PowerWrap Wood including premelter vor EVA & PUR, automatic format adjustment, printer, trimming station and synchronised cutting saw

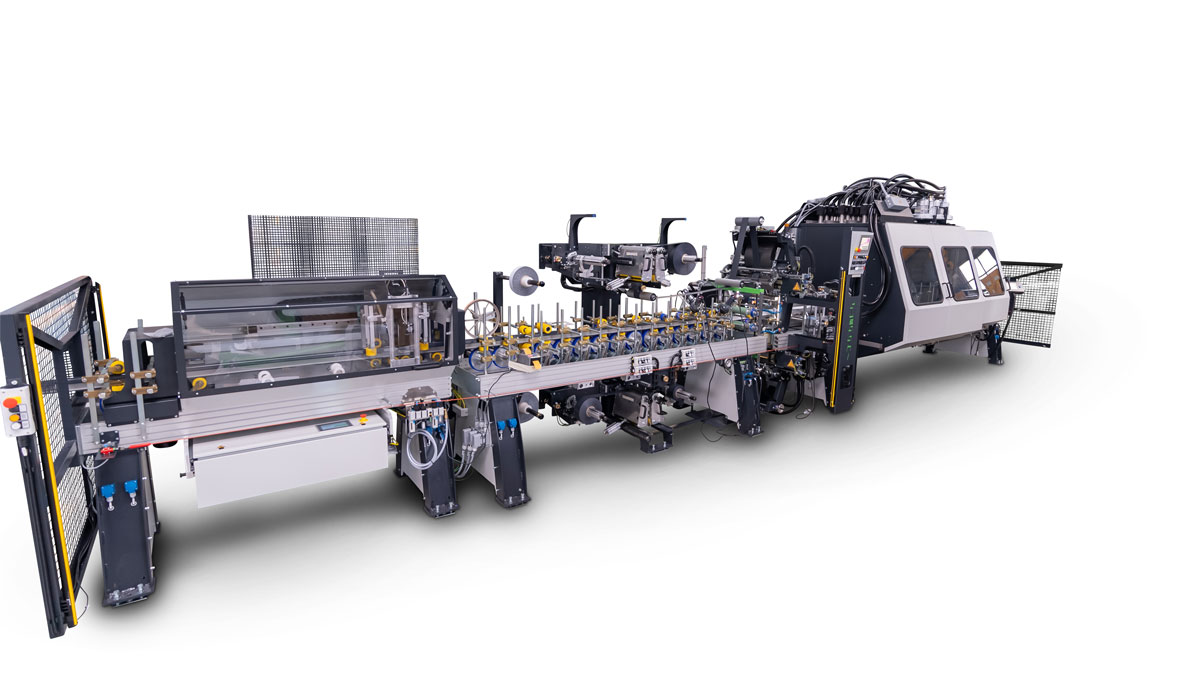

Offline foiling of PVC profiles

Example of configuration of MultiWrap Window for simultaneous foiling of both sides including primer application cabin, reel changing system, chipless separating system

Cutting system

Perfect end of a line or productivity boosting retrofit component: synchronised cutting systems "SynCut" that work without profile clamping

Slitting machine

Profile wrapping line wood

Inline PVC profile wrapping

Vacuum application system

Laminating lines