Door frames

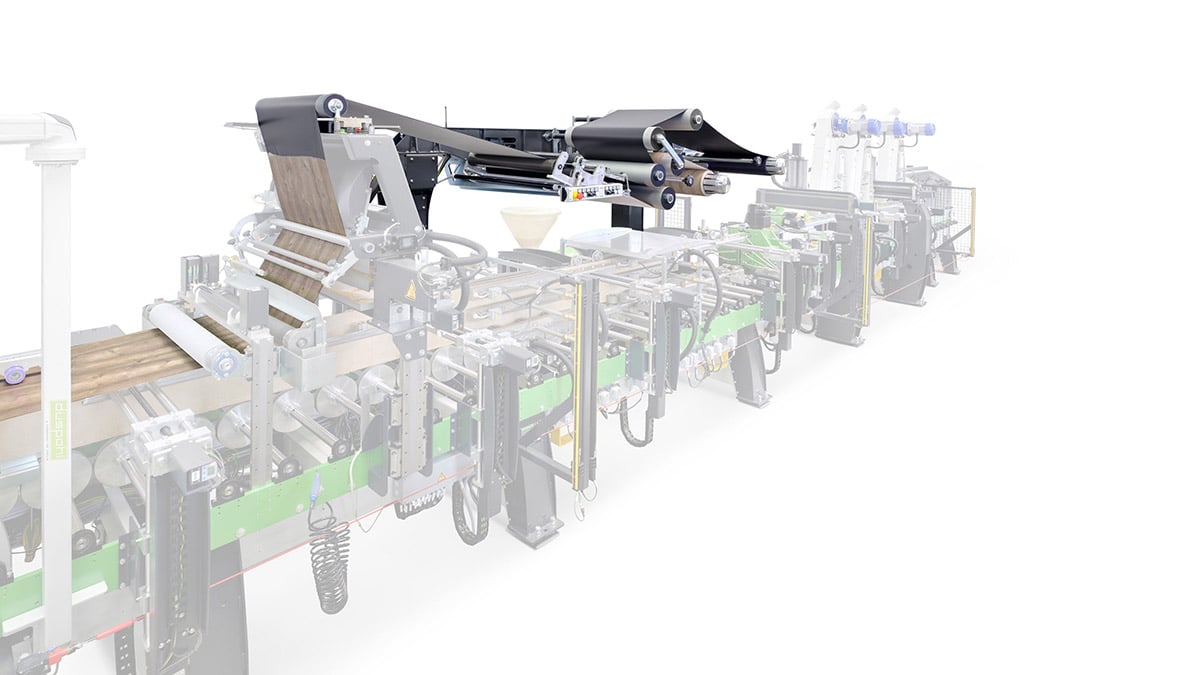

Duespohl designs and manufactures high performance lines for the wrapping of door frames, including trimming units and many solutions to reduce set-up times.

Benefits of using profile wrapping lines for door frames

Most door frames are made of MDF or composite materials that are not aesthetically appealing, so a high-quality laminate foil is used to improve the look and feel. Wrapping door frame profiles can be done on automatic equipment, where a correct recipe is established to optimise performance and deliver maximum quality. Combined with special infeed systems for larger geometries, premelters for granular glue and on-board trimming systems, our solution is an integrated line section ensuring repeatable high-quality output.

Increased efficiency

Automation increases efficiency, so once the recipe is defined, the built-in software monitors the process and adjusts parameters automatically with minimal downtime or operator intervention. Moreover, a highly efficient premelter reduces energy consumption significantly for greater cost-efficiency.

Improved quality

When Continuous Pressed Laminate (CPL) is used, especially on frames presenting sharp corners with a radius <3 mm., you will benefit from our CPL tool package, designed specifically to overcome any problems working with different CPL types. For example, there is a difference between black and white CPL which affects the working temperature of the wrapping equipment. Once you set the temperature, the software automatically adjusts the working temperature to suit the laminate. This leads to consistently high quality throughout production regardless of CPL type or colour. With additional equipment, we make sure that the foil adheres well and does not rise up and get loose at the radius and we pretreat the CPL as well to make it more flexible for the smallest possible radius.

Wider range of design possibilities for door frames

We supply a special infeed system which handles large-size frames and different shapes and geometries.

Do you need advice to choose the best machine for you?

We’ll help you to find the best door frame wrapping machine for your project.

Highlights

-

Central width adjustment for fast set-up when wrapping same geometry with different width

-

Special solutions for work pieces with lateral flank

-

Different degrees of automation, depending on your requirement

-

Energy efficient premelter and internationally renowned slot coater included

-

Each line will be customised

-

Large selection of efficiency boosting and quality assuring components

Our lines & components

MultiWrap Wood

MultiWrap is a real all-rounder in profile wrapping which offers you a wide variety of configurations.

Your individual configuration of this profile wrapping machine for wood (composites) is always based on the requirements of your specific project.

Ideal for

- Plinth panels & skirting boards

- Profiles for door frames

- Picture frames

- Other profiles made from wood (composites)

PowerWrap Wood

The PowerWrap is the premium model for your most exacting technical demands and highly industrialised production. It offers you the widest choice of versions and performance in the field of conventional wrapping.Ideal for

- Plinth panels & skirting boards

- Profiles for door frames

- Picture frames

- Other profiles made from wood (composites)

ReelChange Wood

Double unwinding station with automatic reel change and diameter dependent tension control for up to 33% more productive capacity!Ideal for

- MultiWrap Wood

- PowerWrap Wood

- MultiWrap Wide

- PowerWrap Wide