Sustainability

Profile wrapping – a sustainable process

Profile wrapping is an economic process, in which a base material is finished with a decorative surface, mostly made from foil or paper.

The base material is usually made from a wood composite like chip board, MDF (medium-density fiberboard) or from PVC (polyvinyl chloride). One of the most important applications in the wood sector is furniture production, whose demand could never be met if only solid wood was employed. The use of wrapped profiles is an economic and sustainable addition to traditional furniture production. Moreover, this process offers a large choice of decorative surfaces and treats natural wood resources with care, since more pieces of furniture can be produced with the same amount of timber.

Efficient lines for a minimal use of resources

(and lower costs…)

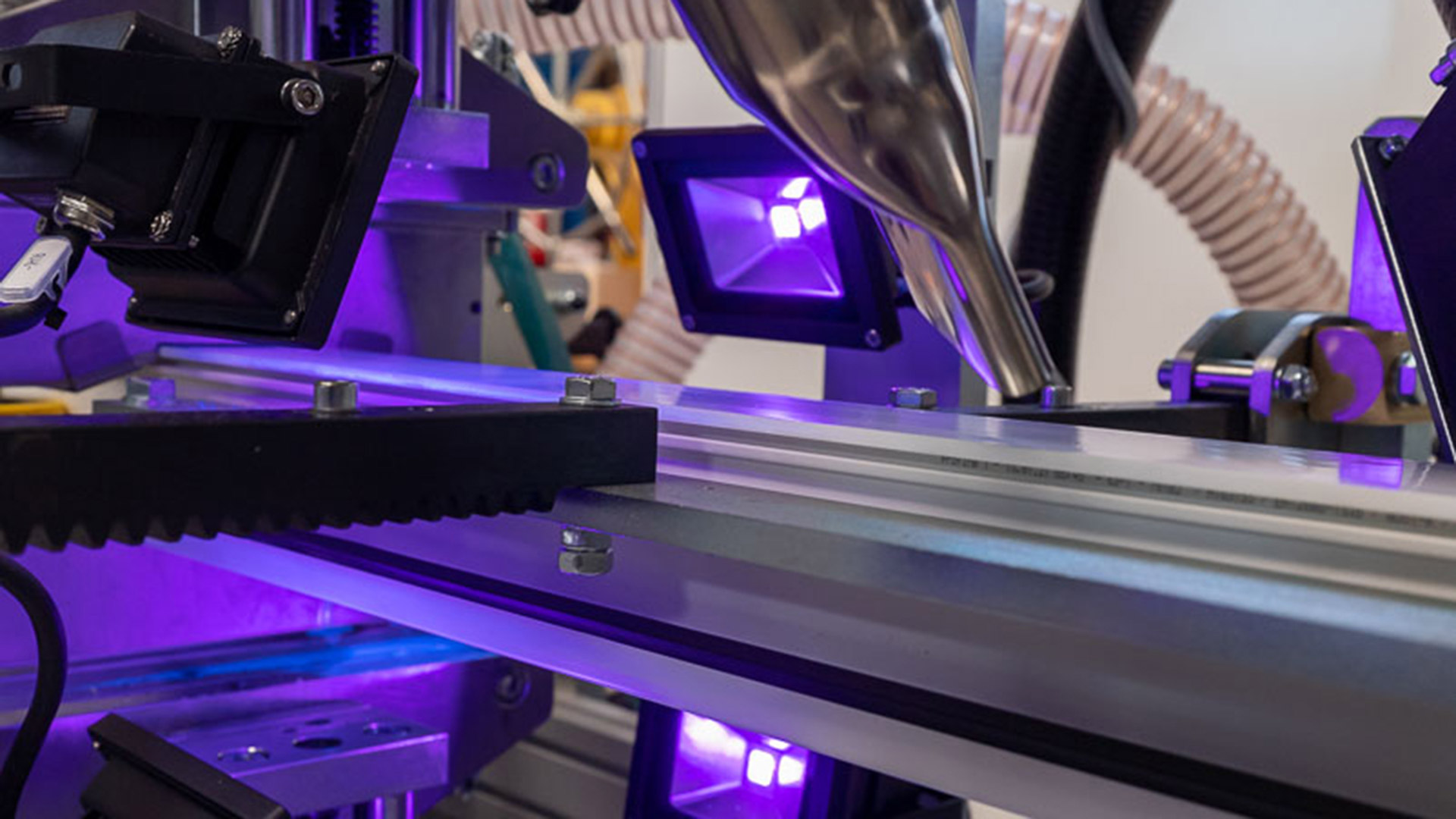

Duespohl’s lines implement the process on efficiently and sustainably producing machines. All lines have been designed to use small amounts of glue, produce a low quantity of waste parts, and work energy efficiently. The foil heating system is one practical example. It heats the surface material to a certain temperature to make sure less glue has to be applied. The reel changing systems are another important example. They enable a changeover of surface material during the on-going production, avoiding a stop and restart for every reel change. This way, users significantly reduce the loss of profiles, glue and foil due to waste parts that are caused by every stop and restart. This focus on efficiency is not only environment-friendly, it also keeps the ongoing costs of the profile wrapping company low.

An investment that lasts

Another factor, contributing to a sustainable production process is the fact that Duespohl’s lines have been designed to have a long service life. This means that the resources we employ when assembling a line will be used for a long period of time, resulting in less resources being used in total. The minimal use of wearing parts also lowers the maintenance workload, on-going costs and increases productivity. Since we can assure you of their longevity, we grant a 5-year-guarantee on certain components.

Especially for the wrapping of PVC profiles

Primer application system for VOC reduced primers

When laminating PVC profiles, the application of primer is an essential, but unfortunately not very environment-friendly step. Duespohl developed the primer vacuum application system especially for pyrrolidone-free and NEP-free, VOC-reduced primers. This Duespohl exclusive technology works with application heads that are fitted to the individual profile and can be reused 1000 times. Also, their set-up takes only 20 seconds, while cutting felt strips (which cannot be reused!) takes at least 20 minutes.

This solution also has advantages when it comes to product quality since the technology guarantees an absolutely homogeneous application of primer, independently from the profile’s geometry.

Especially for the window sector

Spacers for multiple glazing

Multiple glazing, which is essential for warm homes, is a relatively unknown application of profile wrapping. The more efficient the insulation in the edge bond, the more sustainable the construction and the lower the heating costs. In technical language, we speak of the “warm edge”. In order to realise a “warm edge”, we employ spacers made from insulating PVC between the multiple glass panels. To make sure the gas filled into the interspaces does not leak, those spacers have to be gas-proof wrapped – and this is where Duespohl comes in. MultiWrap Spacer by Duespohl has been designed especially for this application. It even wraps several bars simultaneously in one step. This way, Duespohl contributes a great deal towards effective multiple glazing, an essential prerequisite for energy efficient buildings.