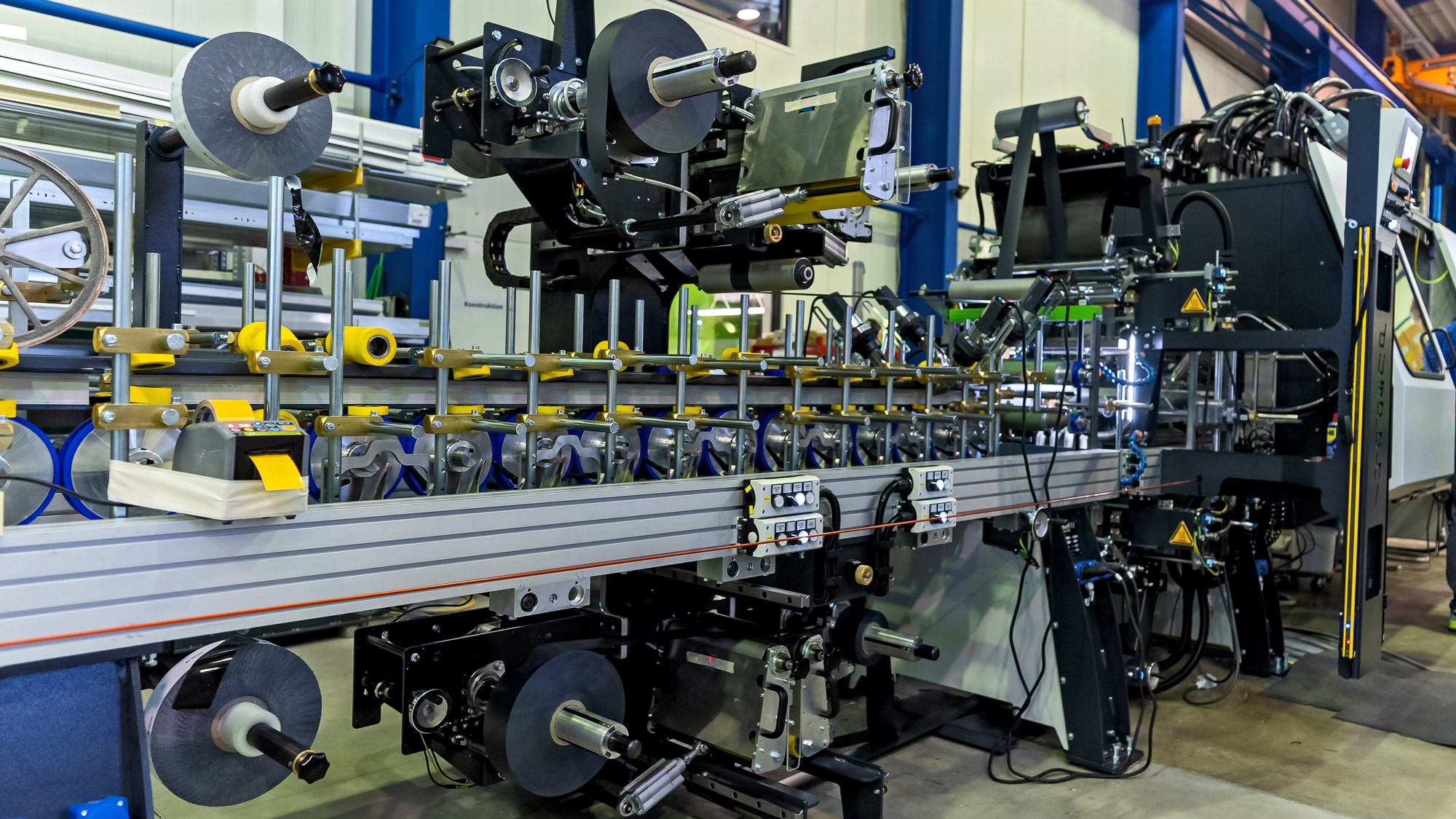

Unwind system: boost your productive capacity with Düspohl

Your foil costs you money, but what really costs you money is time, time spending for changing from one reel to the next, incurring downtime and interrupting production.

Our extensive experience in wrapping equipment, based on highly automated technologies, has taught us over the years to develop multiple unwind systems to keep you moving and avoid stoppages for unprofitable reel changes.

Unwind system: all the applications

Profile wrapping is performed in several sectors, primarily companies manufacturing windows or other profiles in the construction industry. Unwinding systems unwind the reel of foil to be used by the profile wrapping machine.

All the advantages of an unwind system

An unwind system is an essential piece of equipment, but alone, it will not help you avoid production stoppages each time you need to change the reel. If your production process handles many different foil reels throughout the day, you need to upgrade from a single unwinder to a double unwinding station with manual material change enabling you to switch from one material to another without interrupting production.

Düspohl unwind system: high quality and innovation for your business

Düspohl unwinding systems fit ideally into all our wrapping machines and can be used offline as well. The double unwinding station with manual changeover is great for offline profile wrappers, whereas connected machines require automatic slow-down solutions so that the line slows down just before reel change. Integrated control systems allow you to program the running meters you need to use for a job, and if a new colour is used these systems recognise when you need to switch from the finished reel to the next. All our unwinding units feature tension control to protect the foil from damage and stretching. All you need now is a solution which enables you to change from one reel to the next without losing precious production time.

ReelWizard, the automatic reel changer system

ReelWizard is great for window wrapping lines. It enables non-stop wrapping with 6 different thermoplastic decor foils, making sure the joint is always placed between two profiles. The required distance between profile bars is managed automatically, and kept as short as possible to ensure that the following wrapping process will not be disturbed.

ReelChange Wood

ReelChange Wood is a double unwinding station with automatic reel change and diameter-dependent tension control. This is a high-performance solution which enhances your production capacity by up to 33%. Material tension is constant as the break force adjusts automatically to the current reel diameter, thus avoiding damaged foil.

ReelChange Window

ReelChange Window is an automatic easy-to-operate solution for wrappers processing. It features two unwinding shafts and a splicing unit, which connects the two web ends together while the machine is running. With a small footprint, it also uses constant braking power for even glue application.

Düspohl’s double unwinding station

Featuring a tension control system, the final product is processed reliably and constant quality is achieved. Our double unwinding stations can be used for sensitive materials and due to their finely tuned technology, will prevent hairline cracks in acrylic layers of sandwich foils.

Düspohl’s single unwinding station

This unwinder works with all kinds of wrapping material and implements automatic tension control to deliver constant quality. It enables high process safety, since it prevents tearing and unintended running of decorative material after the machine stops.

Unwind system and automatic reel changer system are solutions all profile wrappers will find beneficial. Meaning less downtime and superior productivity, let us at Düspohl help you select the correct machine according to your needs.

Contact us and one of our experts will deal with your enquiry soonest.