Profile wrapping basics

What does profile-wrapping mean?

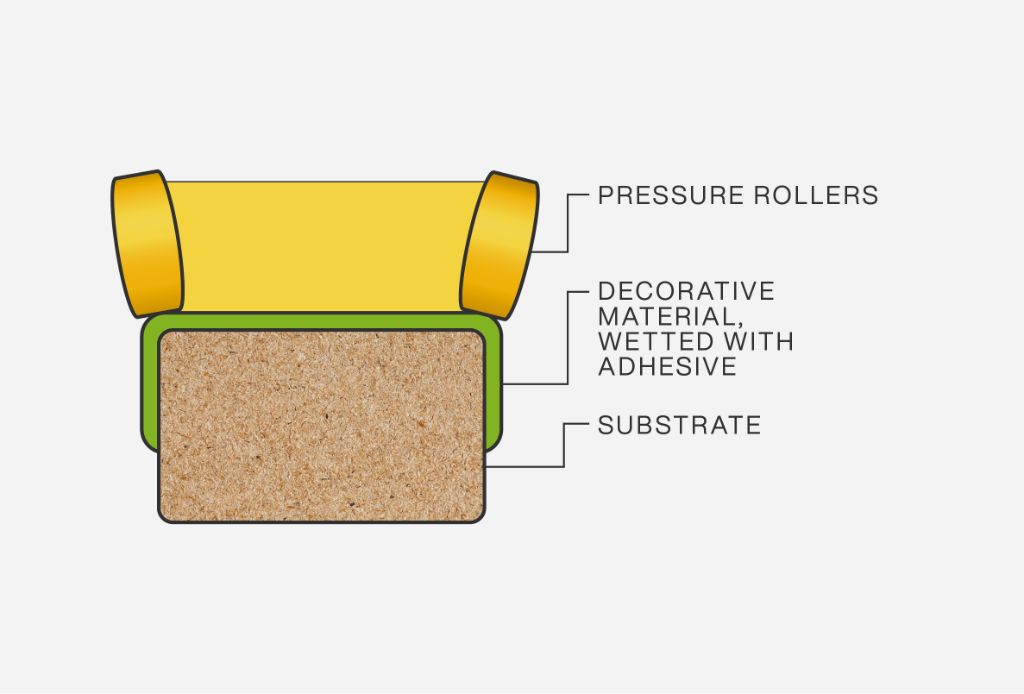

Profile wrapping is a process by which a decorative surface is laminated onto a substrate in linear form. This is done by means of a profile wrapping machine.

Synonyms: foiling / laminating / profile wrapping

Profile wrapping: the process

Profile wrapping is a surface finishing process that offers a large choice of different patterns, colours and qualities, going from paper to PVC (polyvinyl chloride), PP (polypropylene) or – more classic – veneer and other suitable material.

Applications of profile wrapping

The main applications of profile wrapping are:

- wood (composite)

- PVC processing industries (production of furniture, window manufacturing,…)

That is why this kind of surface finishing quickly adapts to new trends in decoration – whether it is a certain wood type, concrete or metal look.

Several decades ago, a decorative surface - mainly wood veneer - was manually laminated onto a substrate. Profile wrapping machines were invented because of the increasing demand for furniture at the beginning of the 1960s.

Apart from this, the cost and price pressure as well as the requirements of the customers regarding the surface design played a substantial role.

Since the process ennobles, among others, residual materials like wood chips converted to mdf profiles, it supports an economic and sustainable furniture production.

One of the first profile wrapping lines was built by Mr. Reinhard Duespohl

who founded the company in 1967.

All the advantages of profile wrapping

One major advantage of profile wrapping is the flexibility it offers in terms of design. Whatever you can print on paper or produce as PVC surface material, can decorate the profile. Especially in times of higher individualisation, this flexibility has become an important factor.

Also, profiles with a wrapped surface obviously have improved qualities like higher resistance against UV rays, humidity or other influences.

Working with veneer as surface material, profile wrapping allows you to produce pieces of furniture with an authentic wood look.

Profile wrapping is

all around

Many items you see every day in your house or apartment have been wrapped. Here are some typical examples:

Profile wrapping

by Duespohl

Duespohl creates and delivers profile wrapping lines for wood (composites), PVC and suitable metal substrates. Most of our lines process hot melt glue that allows for high production speeds and a consistent top surface quality.

The solutions range from entry-level lines for the sporadic wrapping of easy profile geometries to highly industrialised solid lines for 24/7-three-shift-production plants and the most complex profiles, including 360° wrapping.

Discover our profile wrapping

lines for PVC or wood

composites

Profile wrapping solutions: efficient and reliable

In the sector, we are known as the most innovative profile wrapping lines manufacturer.

We integrate the latest technological possibilities into our machines, control systems and components to make sure our customers produce in the most efficient way, generating high quality output reliably and repeatedly.

The future of profile wrapping made by Duespohl

Automation-wise, Duespohl manufactures classic lines with standard PLC control systems as well as the profile wrapping lines with the highest degree of automation that has been realised worldwide: the RoboWrap.

This line integrates six-axes robots and an advanced software developed in cooperation with several scientific institutes.

We combine this technological focus with more than 50 years of experience and many smart mechanical and control system related solutions down to the last detail

To learn more

I have no experience in profile wrapping and would like to find out more

I am familiar with profile wrapping and would like to find out more about Duespohl’s products

I am a window constructor who buys wrapped profiles and would like to find out more about starting profile wrapping

Do you have a project to discuss with us?

We’ll help you find the best profile wrapping solution for your industry.

FAQ on profile wrapping

In previous decades, a decorative surface was manually laminated, mainly using wood veneer, onto a substrate. Increased demand for furniture at the beginning of the 60s was the reason profile-wrapping machines were developed.

Beyond that the pressure on costs and prices as well as the requirements of customers regarding the surface design played a substantial role.

One of the first such machines was built by Mr. Reinhard Düspohl.

- Industries processing derived timber products

- Woodworking industry

- Industries processing wood composite materials

- Plastics industry

- Metalworking industry

WOOD COMPOSITE MATERIALS

- Particle board

- Medium density fibre- board (MDF)

- High density fibreboard (HDF)

- Plywood

- "Extruded wood" (plastics+sawdust)

SOLID WOOD

PLASTICS

- PVC (polyvinyl chloride)

- PP (polypropylene)

- ABS (acrylonitrile-butadiene-styrene)

- Expanded polystyrene

- and others

METAL

- Aluminium

- Steel

- Others

Wood veneer

Wood veneers are divided into two major groups: rotary cut veneer and sliced veneer. Sliced veneer is the most commonly used veneer in profile wrapping. The complexity of the core material dictates the quality of veneer to be used.

Manufactured fleece-backed veneer, as a fleece is glued on the back of the veneer. The veneer becomes more flexible due to the glued-on fleece.

The quality of symmetric and asymmetric finger-joint veneer is visible after the lacquering process. In the case of poor quality, two different pigmentations are visible. Different pigmentations are avoidable using veneer with an aluminium indicator.

Veneer with an aluminium indicator is always in roll form. An aluminium strip is applied at the joint between the veneer sheets. This type of veneer needs to be ordered with a specified sheet length within the roll of veneer. The sheet length needs to be 1’’ longer than the profile it will be applied to allowing for some length variations in the substrate. The advantage of the aluminium indicator is, that the finger-joint strip will not be placed on the profile and ruin its aesthetics. This is accomplished by using sensors on the machine to pinpoint the position of the aluminium indicator at the joint. The signal is used to position the substrate with the aluminium indicator in the veneer roll. Doing it this way, the beginning of the veneer sheet is certain to be synchronous with the beginning of the substrate.

Paper

Different paper types are available for profile wrapping. Paper for profile wrapping is usually made like a sandwich. It starts out with the base paper that is also referred to as the backer. The backer is available in different colours and different weights. The second layer is the decorative layer. The decorative layer can be of a solid colour or with a printed pattern. Usually 30g paper, this decorative layer is laminated to the base paper. The colour of the finished paper depends on the colour of the base paper. These papers can range from 30 to 300 g and more. Most commonly used papers are 60 or 80 g papers. They can be wrapped around very complex profiles and at the same time they are not as fragile as 30 g paper. Paper can be wrapped around sharp edges (with the exception of very heavy papers).

Laminates

Laminates are decorative surface papers impregnated with melamine resins and then pressed over strong paper core sheets impregnated with phenolic resin. These sheets are then bonded at pressures exceeding 200 kg/cm2 at temperatures approaching 150°C. Finished sheets are trimmed and the backs are sanded to facilitate bonding. Laminates are more difficult to wrap in comparison with wrapping paper, because papers are more flexible. The variety of laminates ranges from high-pressure to low-pressure to continuous laminates. There is a difference in the way these laminates are manufactured as well as in the flexibility of the material. Sharp edges are not recommended. For the flooring industry the laminates are coated with aluminium oxide.

In case of profile-wrapping with laminates, an extremely long wrapping zone is necessary. The temperature of the laminate, if corners are to be wrapped, must reach 300° C in the relevant area.

Vinyl (films)

There are many different types of vinyl available. The most commonly used materials are hard/soft PVC and PP. Vinyl can be of a solid colour or have a printed pattern. Different topcoats are available for interior or exterior products.

Interior

No special requirements.

Exterior

The vinyl has to be durable against ultraviolet rays. A special vinyl with a wood-like surface (veneer characteristics) and aluminium-like surface (aluminium characteristics) is available for exterior application, which is mainly used by the PVC window industry.

The newest development is a thermoplastic film for the decorative finishing of windows, doors and other building elements. The film is also suitable for regions with harsh climates, because of a higher weather and temperature stability. Under difficult conditions foil also possesses outstanding colour and gloss stability. Before glue application, the processing temperature of “Renolit-Fast” has to be 80°C with strict tolerance levels.

Hot melt glue

Today hot melt glue is the most common glue used in the profile wrapping industry. Main advantages in comparison with other glue types are: high combination potential between materials, higher transport speed of the profile wrapping machine possible.

The difference between filled and unfilled hot melt glue is not visible. Only the weight differs. Filled glue is heavier than water. We strongly advise against using filled glue for a slot coater.

The difference between “non humidity-reactive” and “humidity-reactive” adhesive is that humidity-reactive hot melt glue is received during the interlacing of a chemical compound (isocyanates) with the humidity from the air. After the interlacing is finished (approx. 3-5 days) it is impossible to re-activate and/or liquefy the glue. The developed adhesive compounds possess extreme temperature and water resistance.

Non-humidity-reactive glue:

- EVA (ethylen-vinyl-acetate):

By the abbreviation EVA we mean a copolymer, which is made of ethyls and vinyl acetate; for over 30 years the basis polymer for hot melt glues. The cost/performance ratio of EVA is good. Disadvantages of this product group are: limited resistance to heat (re-activation temperature: 80 – 100°C) and humidity (no exterior use). - APAO (amorphes-poly-alpha-olefin), abbreviation PO (polyolefin)

This abbreviation stands for several terms: polyethylene(PE), polypropylene (PP), polybutylene (PB) et al. For adhesive production these pure polyolefins are only negligibly suitable. Addressing a wider interest are the amorphous polyolefins manufactured in a special procedure as well as their co- and terpolymeres, which is then commercialised under the comprehensive term amorphous-poly-alpha-olefin (APAO) or in short polyolefin (PO). The main advantage in comparison with EVA is superior heat resistance (re-activation temperature 110 – 130°C). PO is not suitable for exterior applications. High temperature resistance and relevant demand for high melting energy reduce the capacities of all available melting aggregates up to 50 %.

Humidity-reactive glue:

- PUR (polyurethane-reactive)

The abbreviation PUR stands for single component, humidity-reactive polyurethane hotmelts. The PUR glue type fulfils the highest requirements regarding temperature-resistance, water-resistance, steam-resistance, detergent-resistance and solvent-resistance. The main advantages compared with EVA and PO are: High heat and water resistance. PUR adhesives are suitable for interior and exterior use without exception (all materials). PUR glue comes in block form (blocks weighing 2 – 18 kg) and barrel form with 200 kg/barrel. One producer offers PUR granulate too. The glue in block form has a smaller surface area than granulate, which reduces the danger of humidity interlacing. Due to the comparatively low working temperature, PUR is most suitable for thin thermoplastic films.

- APAO-R (amorphous-poly-alpha-olefin-reactive)

For more details regarding the abbreviation part APAO, see APAO. The addition R means reactive. The APAO-R glue is on polyolefin basis with reactive characteristics (see PUR). The adhesive is suitable for interior and exterior use and is offered in block form. APAO-R glue is used more rarely.

Water-based glue

- PVA, PVAc, ...,

Water-based glue, with water portion amounting to up to 50 %, has some disadvantages compared with hotmelt glue. In production the energy consumption is very high and the production speed very low, because the water portion needs to evaporate. Wrapping options are reduced (only suitable for substrates with a simple profile).

Solvent-based glue

- Polyurethane, ...,

Due to new emission protection legislation, it is not recommended to invest in a machine or line that operates with a solvent-based glue.

Formula:

Width of overlay material in metres X Transport speed in m/min X 60 minutes X grams per m² in kg/m² = mass of glue in kg/h

Example:

Overlay material 250 mm = 0,25 m X 40 m/min X 60 minutes X 50g/m² = 0,05 Kg/m² = 30 kg/h.

If you wish to use more than ⅔ of the capacity of our melting units, we recommend conducting tests. The melting capacity varies dependent on glue type and manufacturer.

The following end products may be made of the listed material combinations. Please keep in mind, that the table below reflects only a fraction of possible material combinations. Other combinations are possible.

The decision as to which adhesive should be used also depends on the temperature influences on the transportation route or ultimate destination of the wrapped end product. Therefore, the material combination specified before can change.

|

substrate → end products ↓ |

particle board | MDF | HDF | plywood | wood | extruded wood | plastics | metals |

| furniture parts (interior) | EVA/PO | EVA/PO | EVA/PO | EVA/PO | EVA/PO | EVA/PO | EVA/PUR | EVA/PUR |

| furniture parts (kitchen, bath) | PUR | PUR | PUR | PUR | PUR | PUR | PUR | PUR |

| panels | PO | PO | PO | PO | PO | PO | PO | - |

Substrates that are not made from derived timber products, plywood, wood or extruded wood (non-wood substrates) may require some treatment prior to wrapping. In any case the selected glue manufacturer should be consulted to establish a recommended treatment.