Press lines for parquet flooring: innovation and challenges

Parquet flooring is synonymous with high quality and adds a sophisticated touch to any environment, a warm welcome to those who will tread upon its surface. Under the noble surface of each plank or slat you will find an HDF core or layers of plywood that have been assembled to ensure stability for an even surface once they are laid together. Discover in this article Düspohl's press lines for parquet flooring.

Press lines for parquet flooring: applications

Manufacturers of parquet flooring use several different solutions, ranging from solid wood to engineered planks and laminate with a mixture of layers that can be simple fibreboard to a combination of softer woods and plywood. When the surface is not the hardwood itself, it is a veneer which is applied directly to the uppermost layer. An important aspect, regardless of the surface finish which is a question of aesthetics, is the stability of each slat which will be assembled together with other slats to cover the floor. A tongue and groove design is used in the majority of cases, facilitating installation.

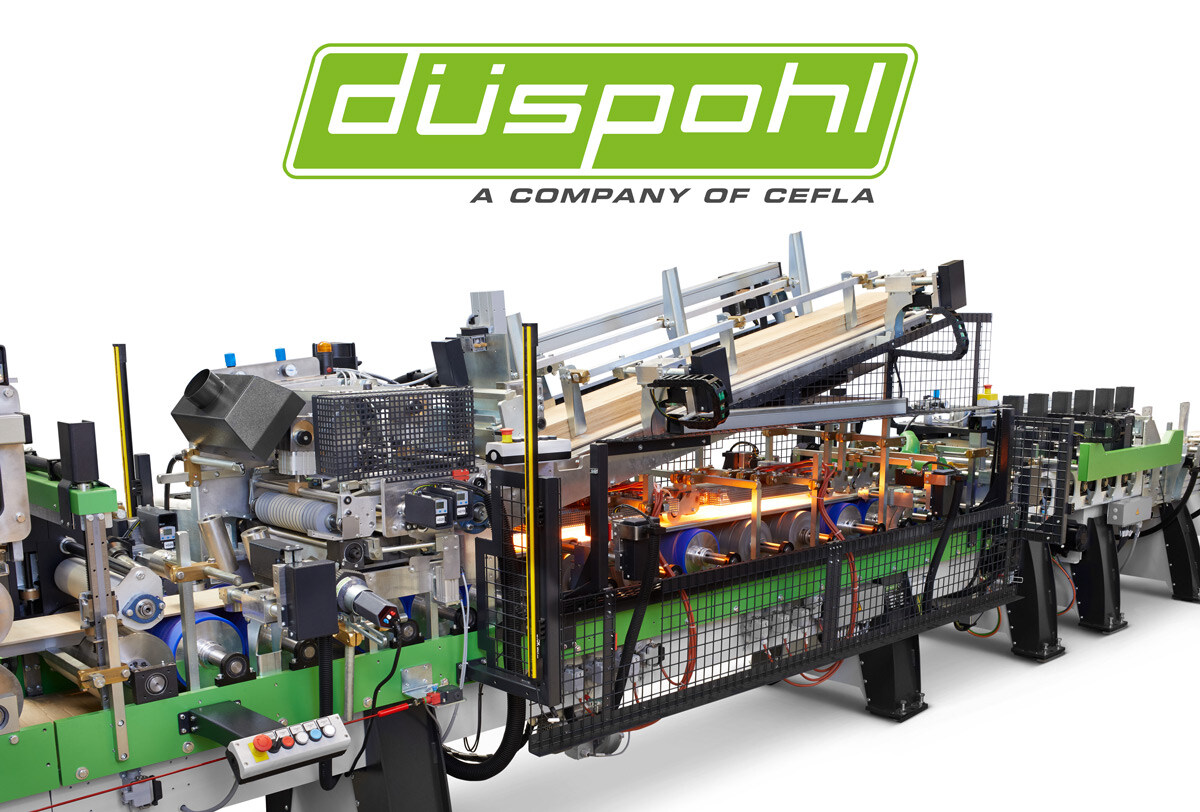

XPress Parquet

Producing parquet not only needs to aim for a strictly flat plank and the rigidity to keep it flat once laid, but must account for large volumes and efficient processing. XPress Parquet is an automated all-in-one solution and compact by design.

Automation improves efficiency and XPress Parquet features an automatic infeed system, premelter and synchronized saw, ready to process 250 and 400 mm working widths.

Press lines for parquet flooring: benefits for your business

XPress Parquet applies the top layer using PUR hot melt glue, so that the slats keep their shape. This makes subsequent processing easier to manage, maintaining high levels of efficiency through all production stages. Installation is also easier with a high-quality, flat plank.

XPress Parquet reaches speeds of up to 100 m/min, which is as much as 300% the output of other automated manufacturing methods seen on the market today. Moreover, investment is lower and the floorspace is less than traditional solutions. Low on consumption of all resources, XPress Parquet is high on performance.

Düspohl helps you select the best press lines for parquet flooring, according to your needs.

Contact us and one of our experts will deal with your enquiry soonest.