Slitting machine: simple, safe and efficient

This article will tell you more about applications of slitting machines and what makes a slitting machine efficient. The perfect preparation of the surface material reels simplifies the entire profile wrapping process and is an essential condition for high quality final products.

Slitting machine: common uses and applications

A slitting machine divides a large reel of surface material (mother reel) made from PVC, PP, paper or other suitable material, into narrower reels that correspond to the widths required for the subsequent profile wrapping jobs.

One way is to fix the mother reel at its extremities and divide it by means of a saw - which results in an irregular cut and is only useful for applications in which the surface material applied is wider than the area it has to cover on the profile. In that case, the irregular edge will be adapted in a trimming unit, for example.

Also, this process means that considering the thickness of the saw blade, quite an amount of surface material gets lost.

If the foiling process requires the exact width of the surface material with regular edges, the slitting machine should be of the unwinding-rewinding-type. This means that the mother reel is unwound on one side, passes through a unit equipped with knives which are set to the required widths and then the multiple newly cut reels will be rewound.

Slit machines are deployed both by profile wrapping companies who wish to be flexible and cut their own surface material and by producers of surface material who deliver the cut reels to their customers.

Duespohl has designed and manufactures both types of slitting machines so you can find the ideal solution for your project. When it comes to unwinding-rewinding-slitting machines, Duespohl has developed basic machines as well as a premium model with the highest automation degree possible.

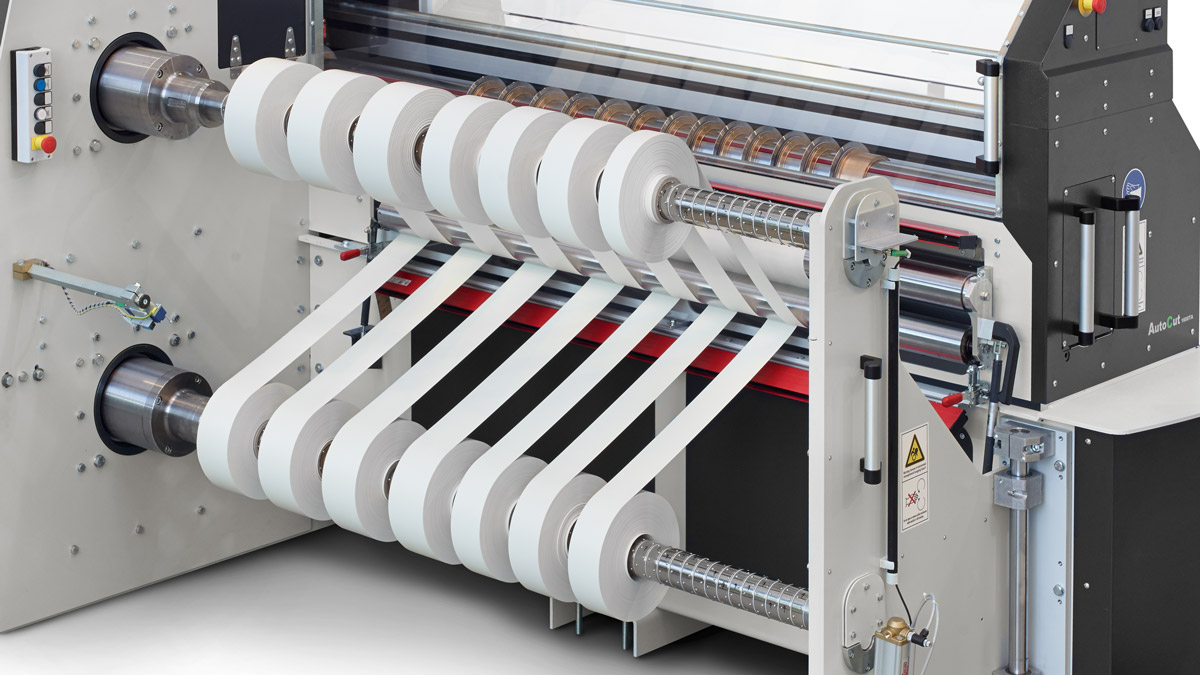

AutoCut, the new Duespohl’s slit machine

AutoCut is the slitting machine with the highest degree in automation you can currently find in the worldwide market. It controls the tension in the unwinding and the rewinding process to avoid stretching or loose rewinding. Also, tension control protects sensitive surface materials from cracking.

Especially when it comes to the slitting machine setup, positioning the - obviously - sharp knives is both laborious and potentially dangerous. To reduce the working hazard potential, AutoCut positions the knives automatically. The operator simply programs the required widths using the easy-to-use touch screen control panel - and AutoCut does the rest of the job.

To make sure the surface material does not only keep its ideal tension, but also position, the automatic slitting machine has been equipped with a web edge control.

In addition to being a maximally automatic slitting machine, AutoCut also features some smart mechanic solutions. Equipped with friction winding shafts, it makes sure reels will be rewound constantly, independ from the different widths.

All the benefits of investing in an automatic slitting machine

Working with an automatic slitting machine, you will save time and money.

The automatic knife positioning does not only reduce working hazard potential, it also reduces setup times to a minimum and increases your productivity as well as flexibility. The exact reproduction of the required widths improves process safety and prevents eventual claims due to faulty final products.

Then of course, an automatic slit machine makes you more independent from the individual employee’s availability. You might have one colleague who knows how to handle your basic slitting machine - but she or he might get sick or go on vacation which leaves you with a machine that requires very exact and sensitive manual adjustments. Working with an automatic slitting machine, you just carry on producing.

Moreover, automation goes along with improved data management. AutoCut can be connected to your ERP, you can prepare job lists at the desk, manage recipes and read out relevant production data.

Since the reel slitting is a preparation of the profile wrapping process, an automatic slitting machine with repeatable settings and reliable product quality is an essential foundation for excellent profile wrapping results.

Automatic slitting machine: discover the innovation

Does working with an automatic slitting machine sound interesting to you? Duespohl also manufactures classic slitting machines for reels of up to 2200 mm and thicker materials. Our Sales Engineers will be happy to give you further advice.

Contact us for a free, unbinding conversation.