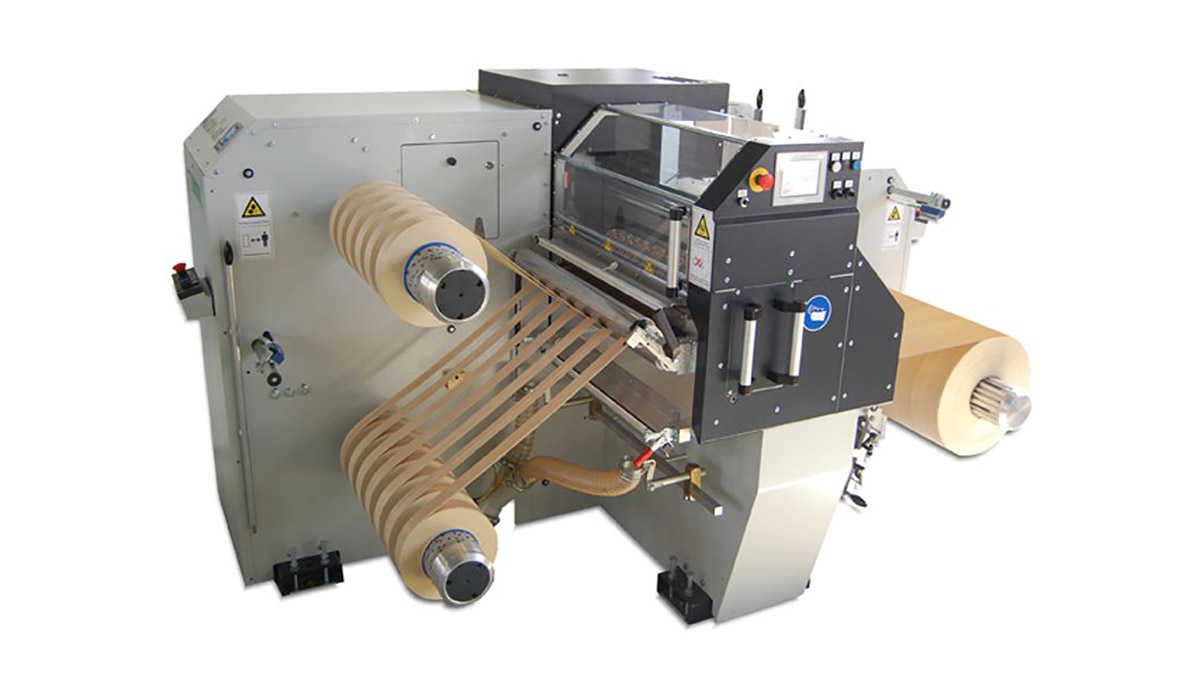

AutoCut

Ideal for

- Surface material

Would you like to receive a free consultation to find out if AutoCut is the solution you need?

Contact us for a non-binding, first conversation.

Description

AutoCut is the slitting machine with the highest degree of automation that is available. The operator has to program the desired widths on the intuitively usable Touch Panel. Then, the machine will drive the upper and lower disc knives automatically to their positions.

Tension is regulated automatically depending on the diameter. It can be set-up to produce an ultra-tight winding or to avoid cracks in the acrylic layers of more sensitive foils.

Thanks to automation and significantly lower set-up times, you increase your efficiency and assure constant results – independent from the qualification of the staff.

Upon your request, we will equip AutoCut with an interface to your ERP.

The data collected such as speed, running meter and machine conditions form an indispensable base for successful production management, including the optimisation of machine capacities.

Furthermore, recipes can be prepared on the PC. Then, all the operator has to do, is to select it on the machine’s control panel.

The standard equipment on this series of machines includes:

-

Automatic knife positioning with a precision of up to +/-0.1 mm

-

Touch screen for programming

-

Automatic braking power control of unwinder, contactless and diameter-dependent

-

Connection to your company‘s network (transfer of process data, programming of recipes)

-

Separate drives for cutting station and upwinding shaft to minimise wearout

-

Standard widths: 400, 700, 1600

The optional equipment on this series of machines includes:

-

Stand-alone upwinding station for slitting edge material

-

Electronic deionisation system

-

Friction winding shafts to compensate differences in the material thickness of the mother reel

-

Auxiliary system to take off the cut reels

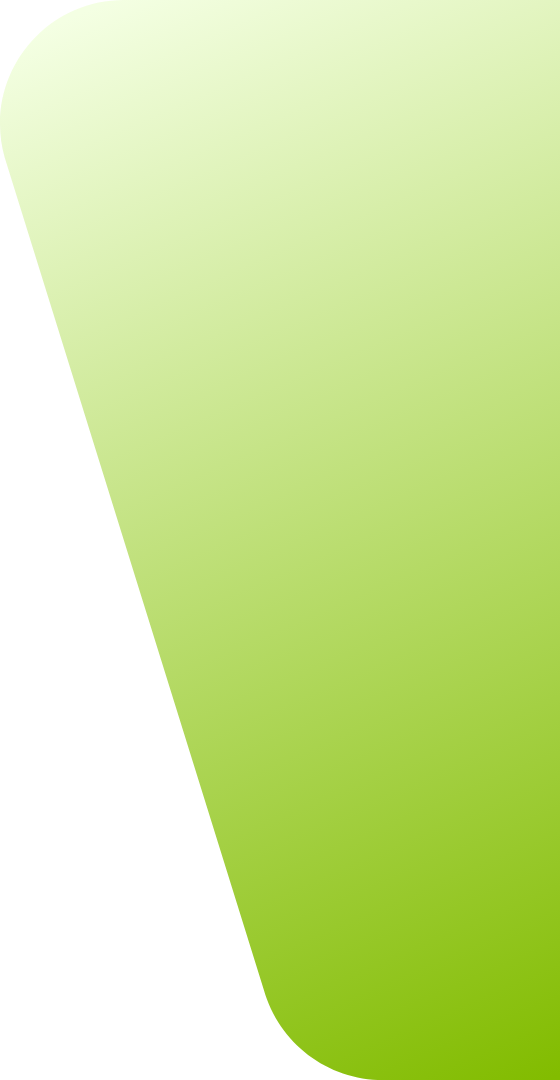

AutoCut 1600

Unwinding unit with automatic diameter-dependent tension control

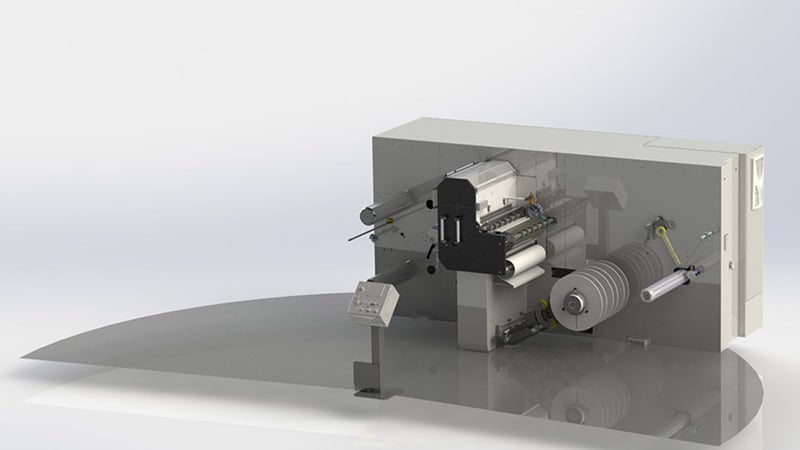

AutoCut 700

Rewinding unit equipped with friction winding shafts

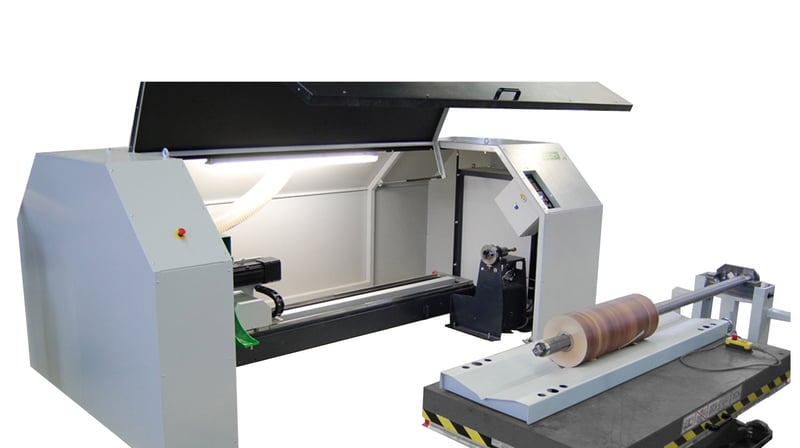

AutoCut 1600

Rewinding unit equipped with friction winding shafts

AutoCut 700

Rewinding unit equipped with normal rewinding shafts

Highlights

-

Minimisation of set-up times and hazard potential

-

High flexibility by optional use of different knife systems

-

Easily accessible thanks to overhung winding shafts

-

Increased productivity

-

Less loss of foil due to residual strip thanks to web edge control

-

Repeatable results, independent from the qualification of the operator

-

Constant tension while winding up, independent from the diameter

-

Constant tension for both sensitive surface materials and ultra-tight upwinding

-

Constant web speed, regardless of diameter

Downloads