PowerWrap Wood

Ideal for

- Plinth panels & skirting boards

- Profiles for door frames

- Picture frames

- Other profiles made from wood (composites)

Would you like to receive a free consultation to find out if PowerWrap Wood is the solution you need?

Contact us for a non-binding, first conversation.

Description

With production speeds of up to 100 m per min., PowerWrap Wood has a unique selling point in this market segment.

It has been specifically designed for the wrapping of wooden and composite material profiles utilising decorative finish materials on reels with a working width of up to 550 mm. Optimally equipped, it realises a nonstop production with fully automatic reel changing system, self-cleaning premelters with a melting capacity of up to 300 kg/h, trimming and milling units and synchronised separating systems.

Every machine will be configured individually according to the customer's particular requirements. PowerWrap is the only model of our product range that can be equipped with core position controlling which avoids undesirable transitions of decorative material on profiles.

The PowerWrap Wood R is available with integrated roller application system and automatic veneer magazine for working with single-sheet veneers.

The standard equipment on this series of machines includes:

-

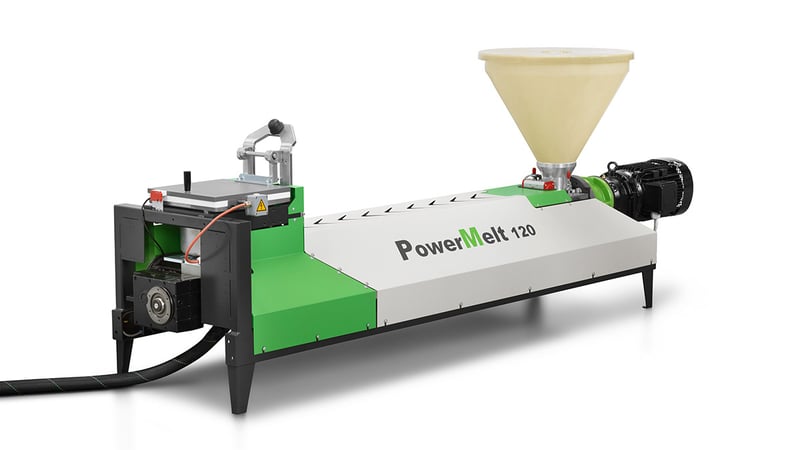

Energy-efficient, high-power premelter (Duespohl)

-

Speed-related adhesive dosing systems

-

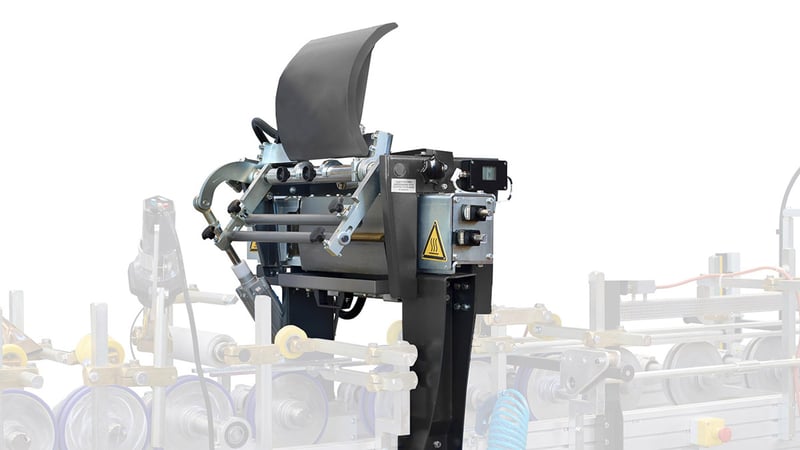

Maintenance-free, infinitely adjustable wide slot nozzle (Duespohl) on version “S”

-

Pressure rollers with tool-free quick-change system

-

Wrapping zone equipped with easy-to-use quick change systems

-

Central width adjustment for transport wheels and/or pressure rollers

-

Transport wheel with tool-free fixing system

The optional equipment on this series of machines includes:

-

Automatic slot nozzle positioning

-

Automatic reel changer

-

Automatic web tension and edge control

-

Automatic workpiece positioning also for veneers from the roll

-

Milling and trimming units

-

Synchronised separating systems

-

Visualisation of process parameters on desktop, management of recipes

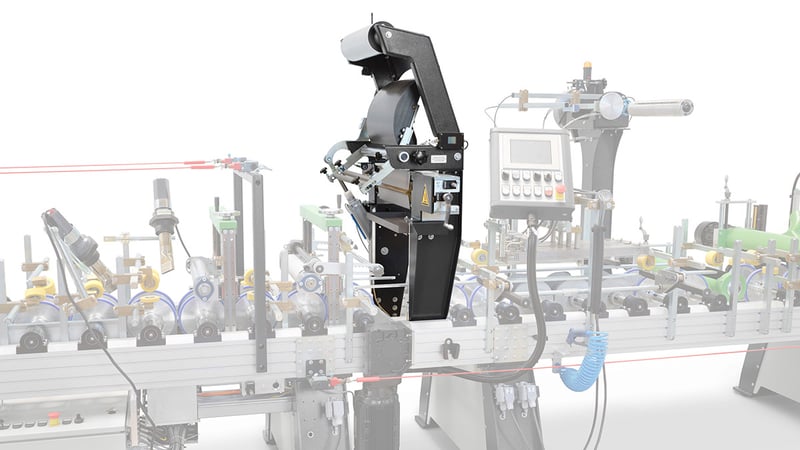

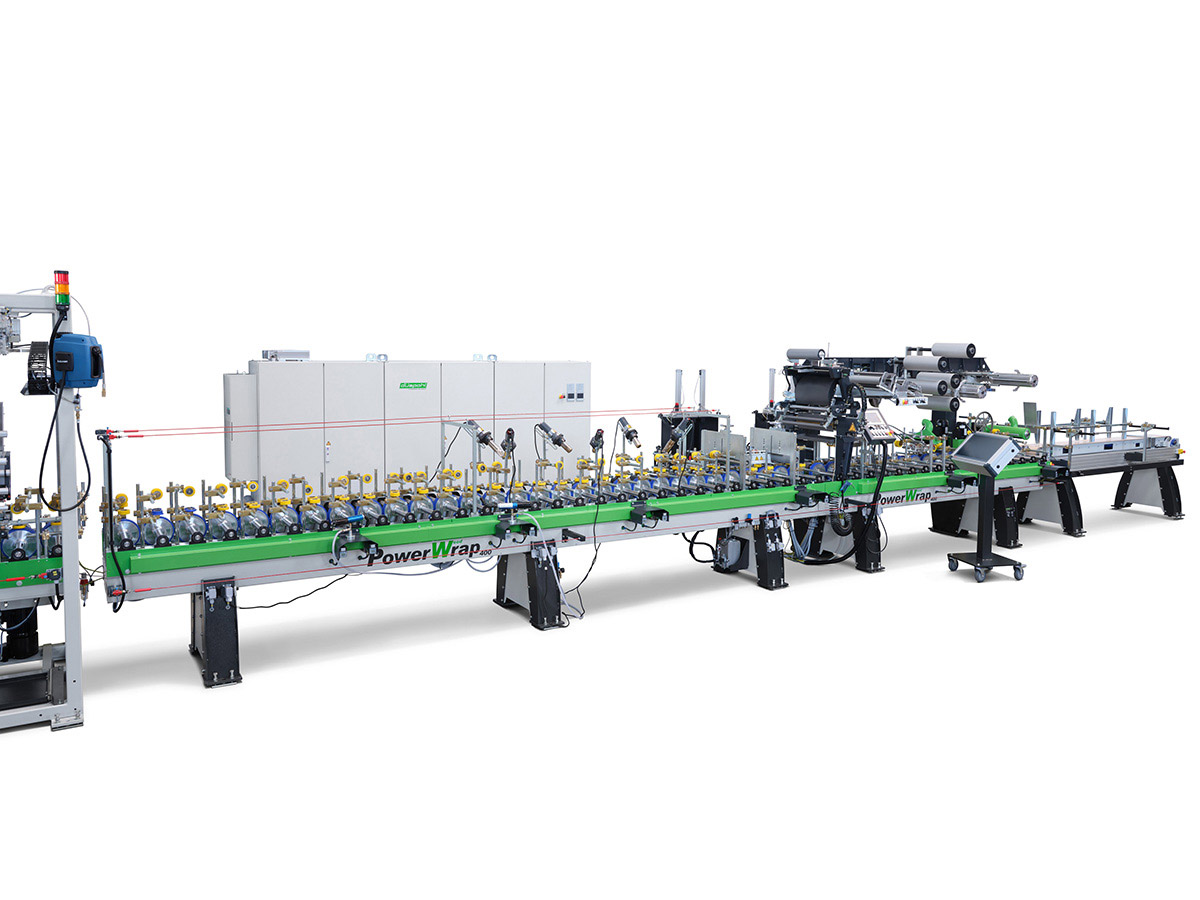

Possible configuration of PowerWrap Wood 400S

PowerWrap Wood 400S featuring ReelChange Wood, infeed belt magazine, UniMelt 80, Foil heating system, Slot Coater, trimming unit, SynCut 360 and free-standing electrical cabinet

First part of PowerWrap Wood 400S

Infeed belt system, ReelChange Wood, Foil heating system, SlotCoater, UniMelt 80, wrapping zone and free-standing electrical cabinet

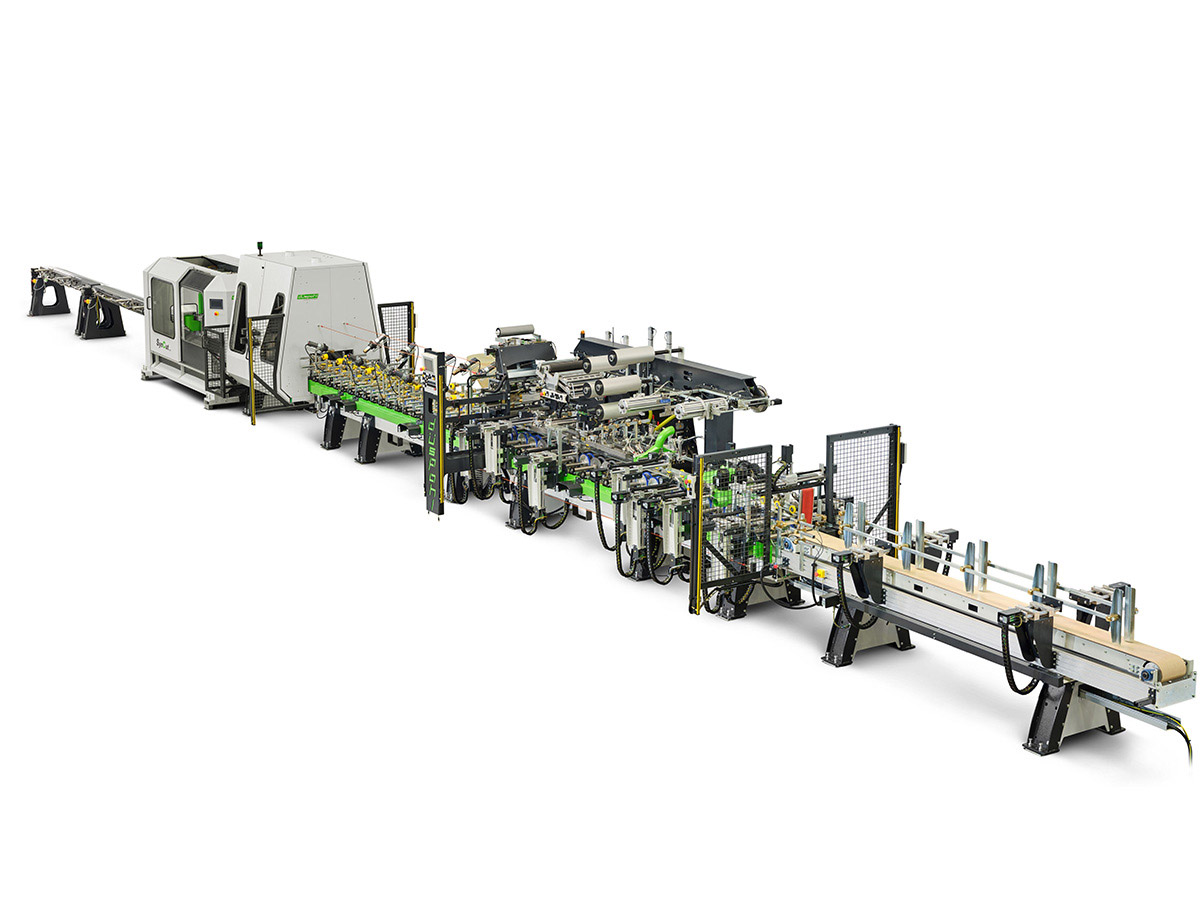

Possible configuration of PowerWrap Wood 400S

Featuring Infeed belt magazine, ReelChange Wood, trimming unit and SynCut 220L. Invisible but crucial: automatic format adjustment

Front view of PowerWrap 400S

Featuring Infeed belt magazine, ReelChange Wood, trimming unit and SynCut 220L. Invisible but crucial: automatic format adjustment

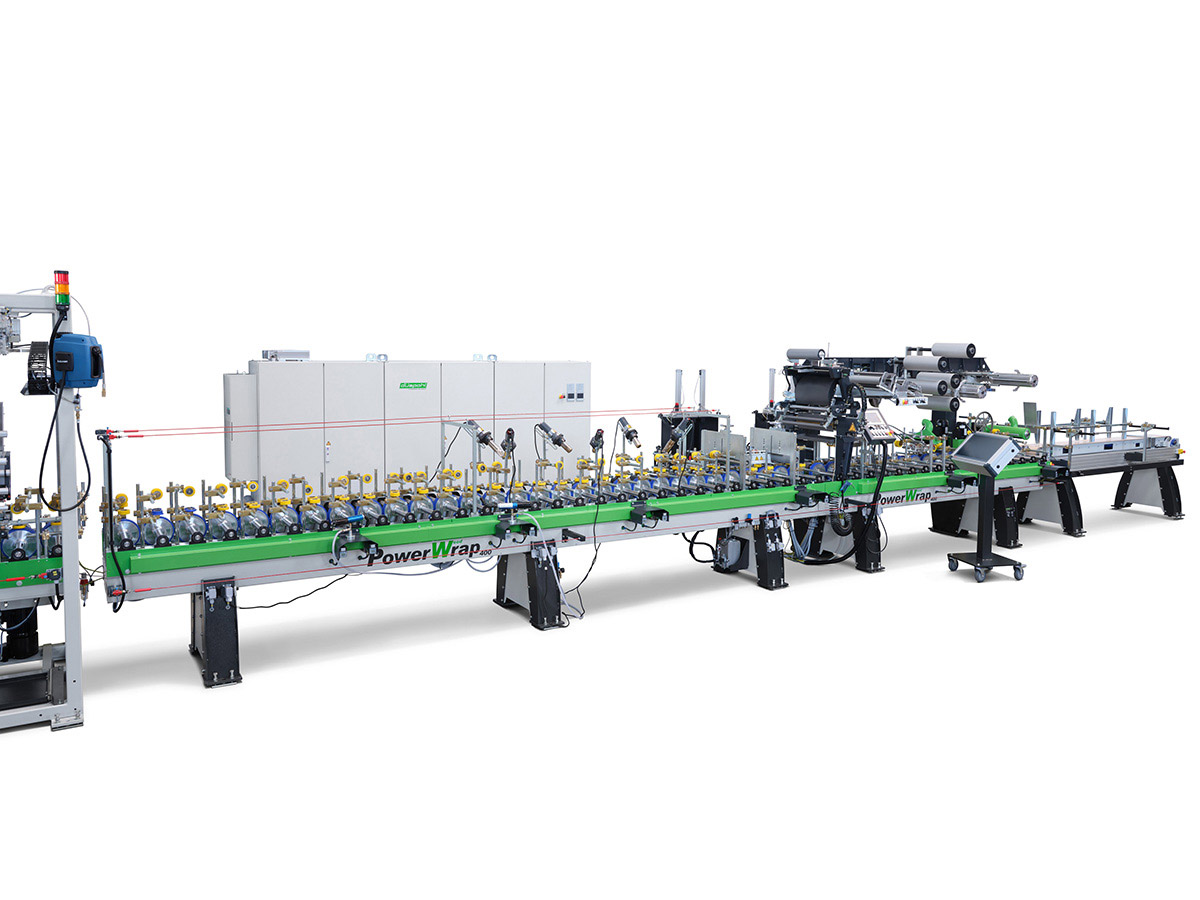

Possible configuration of PowerWrap Wood 400S

Featuring DLBA, ReelChange Wood, Foil Heating System, trimming unit and SynCut 150B

Highlights

-

Automatic format adjustment for fast set-up and maximum process safety thanks to reproducibility

-

Transport speed of up to 100 m/min

-

Maximum power also in 3 shift operation mode

-

5 years guarantee on the mechanic components of the drive system