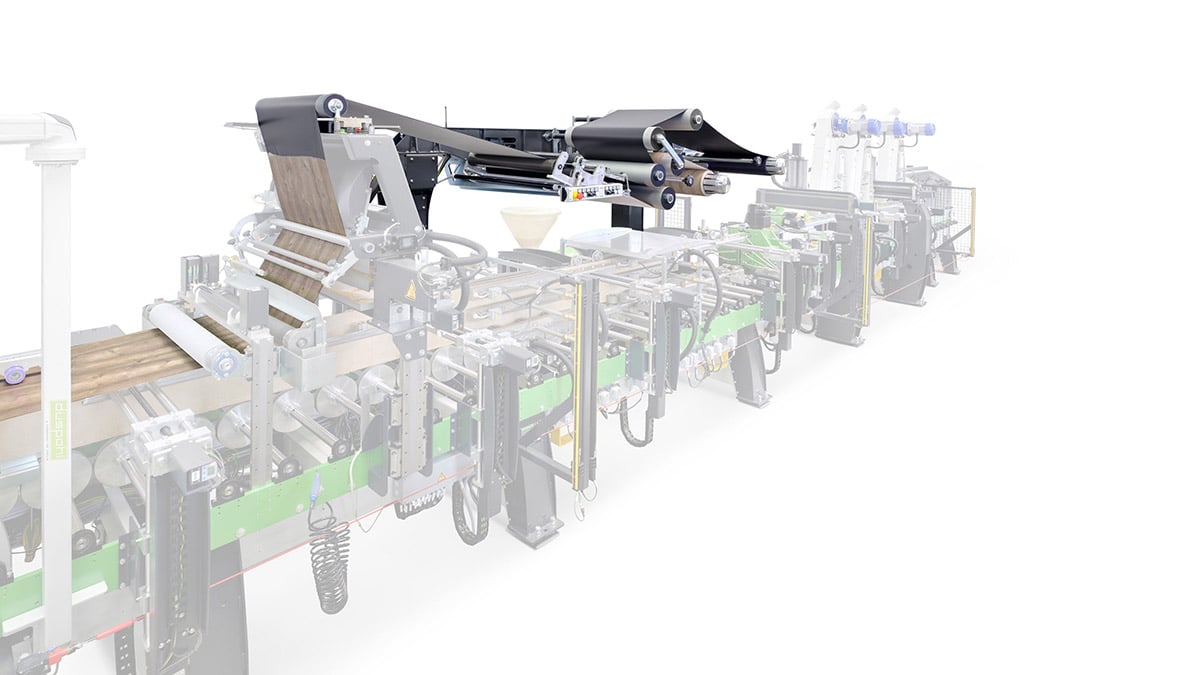

ReelChange Wood

Ideal for

- MultiWrap Wood

- PowerWrap Wood

- MultiWrap Wide

- PowerWrap Wide

Would you like to receive a free consultation to find out if ReelChange Wood is the solution you need?

Contact us for a non-binding, first conversation.

Description

The more and more frequent change of the decorative material reel is one way in which the trend towards higher individualization shows in profile wrapping. Working with a common simple unwinding station, this often means an interruption of the finally successfully running production process.

After changing the reel, the whole process has to be restarted from the very beginning, which means producing waste and waste parts once more.

In addition, when producing at a higher pace, frequent reel changes can become a time consuming factor.

In order to minimize downtimes and gain more time for actual production, Duespohl has developed the automatic reel changer. The ends of the subsequently used reels will be taped together during the production process.

To assure a homogenous application of the adhesive, the automatic reel changer is equipped with an automatically adjusting break. The break force is constantly adjusted to the current reel diameter to make sure that the material tensions stays constant. This way, you also avoid cracks in the foil.

The standard equipment includes:

-

Web edge control for exact positioning of decorative material

-

Sensitive adjustment of the braking power for tension-sensitive materials

-

Set-up aids for easy handling

The optional equipment includes:

-

Foil cleaning and deionisation

-

Foil cutting

Highlights

-

Continuous production

-

Up to 33% more production capacity in comparison to a single unwinding station depending on the material and considering identical production parameters

-

Automatic reel change also in case of material crack or end of reel

-

Constant tension of decorative material enables homogenous glue application

-

Automatic stop of reel when production stops