Premelt technologies: high efficiency for all applications

In this article, you will find out all about premelters for profile wrapping and foiling. The premelt process requires the melting of hot melt glue which bonds the foil to the work piece.

What is a premelt unit and how does it work?

The premelt unit is an essential part in the glue application system of a wrapping machine. It premelts the hot melt adhesive so it can be applied to the surface material. The hot melt adhesive can be PUR, Polyolefin or EVA. The premelter also has to make sure that sufficient melted glue will always be available, no matter how fast the line is running.

Premelt systems: advantages for perfect wrapping results

Adding an energy efficient premelt system that prevents burnings and melts homogeneously is a great advantage since it sets the ground for long-lasting high quality final products.

Duespohl’s solutions for premelting

Duespohl has developed premelt systems that guarantee constant dosing, independent from the production speed and high availability.

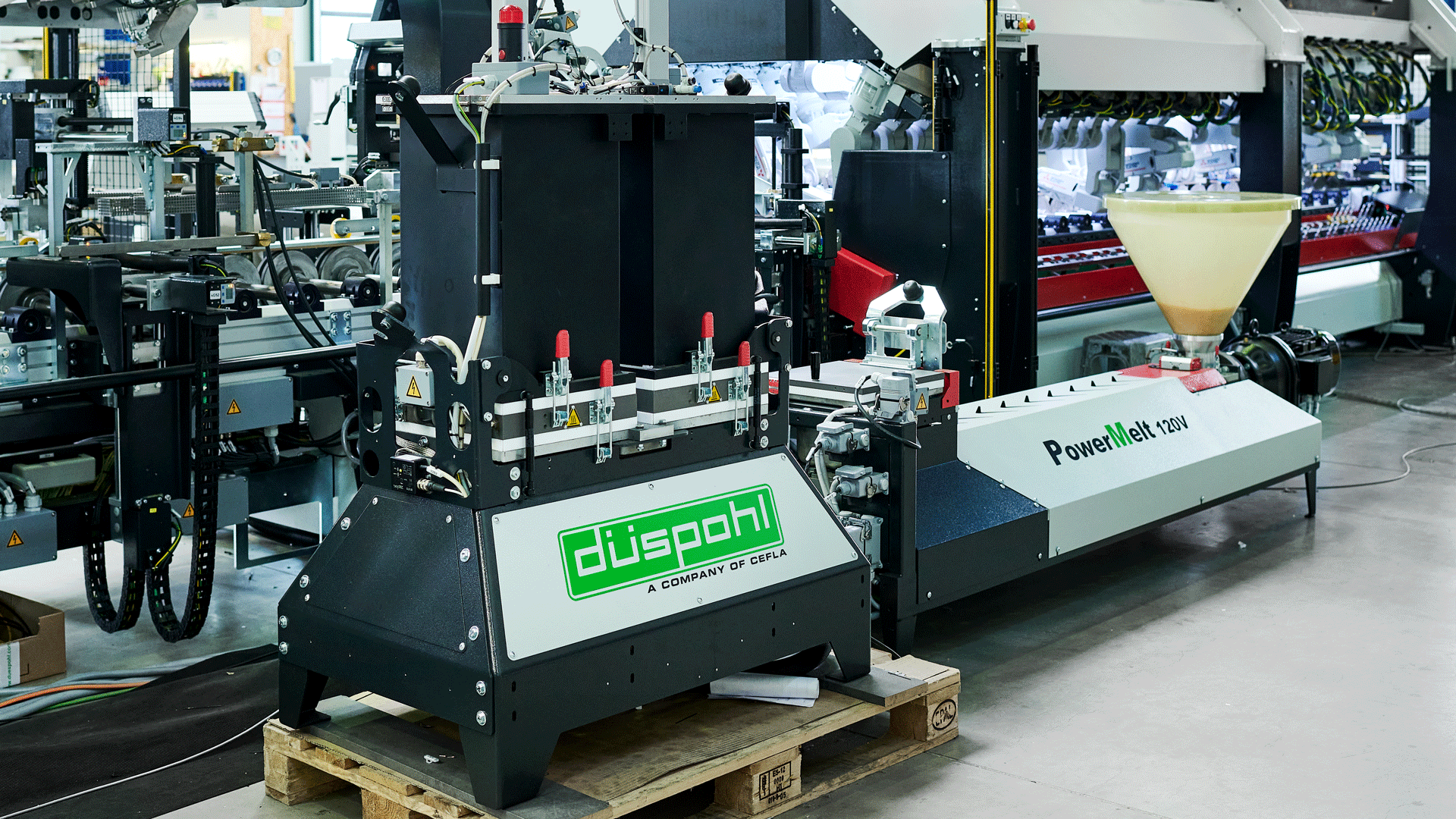

PowerMelt: the premelter for EVA and PO

PowerMelt is an extruder-type premelter and especially energy efficient, since the melting energy is generated exclusively by the drive.

It processes adhesives in granulate form and premelts up to 120 or 300 kg/h of EVA per hour. Your operator will also be happy to work with this premelter since it is a self-cleaning system. Its design prevents burnings and enables refilling while the production is running. Of course, this premelter can be retrofitted to existing lines.

UniMelt: your ally for hot melt glue, PUR, EVA

UniMelt is a piston-type premelter for both granules and blocks of adhesive. Thanks to its design, it is very energy efficient and requires low maintenance efforts. There are no valves nor sealings that have to be replaced. It is also an efficiency boosting retrofit component.

All relevant parts can be reached easily, thanks to the ergonomic design of this premelt unit.

SlotCoater: premelter and slot nozzle

The premelted hot melt glue has to be applied and this is where SlotCoater comes in. The patented slot nozzle applies the adhesive absolutely homogeneously and doses constantly - independently from the production speed. It also keeps undesired particles from being applied to the surface material and causing defective goods.

The factors to consider when choosing a suitable premelter

An important factor when choosing the ideal premelt system is the energy efficiency. Especially nowadays, energy costs are a crucial factor in every production process. Also, a premelter increases productivity if it does not cause downtimes when glue has to be refilled.

In terms of availability, a premelt system should not require frequent maintenance efforts, but work reliably and constantly.

Find out more about Duespohl’s premelters and how they can improve your process.