XPress Parquet

Ideal for

- Parquet

Would you like to receive a free consultation to find out if XPress is the solution you need?

Contact us for a non-binding, first conversation.

Description

Since XPress Parquet pastes the top layer and the base material using PUR hot melt glue that consists of 100% solid material, the boards will keep their shape after pressing- deformations will not occur. As a consequence, further production steps using other machines will run trouble-free and the final customer will find the placing of the parquet an easy piece of work.

With its smart way of operating and high production velocities of up to 100 m/min, Duespohl's XPress Parquet produces up to 300% of the output that other current automated manufacturing processes generate. At the same time, it requires a fraction of the investment volume - and space alternative lines would require. Like all Duespohl machines, it is extremely efficient and resource-friendly.

As a complete solution, XPress Parquet contains the automatic infeed system, the premelter and the synchronized saw. It is available in the working widths 250 and 400 mm.

The standard equipment on this series of machines includes:

-

Automatic infeed system

-

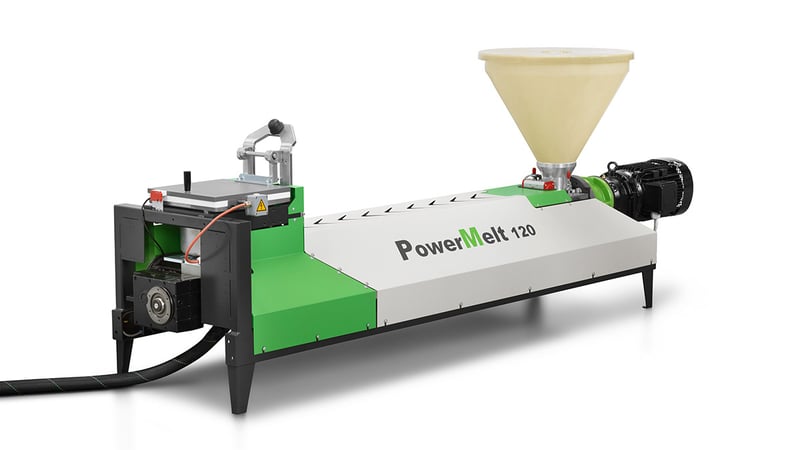

Premelter

The optional equipment on this series of machines includes:

-

Automatic format adjustment for easy and precise set-up

-

Joint connector

-

Automatic separation system SynCut

-

Outfeed system

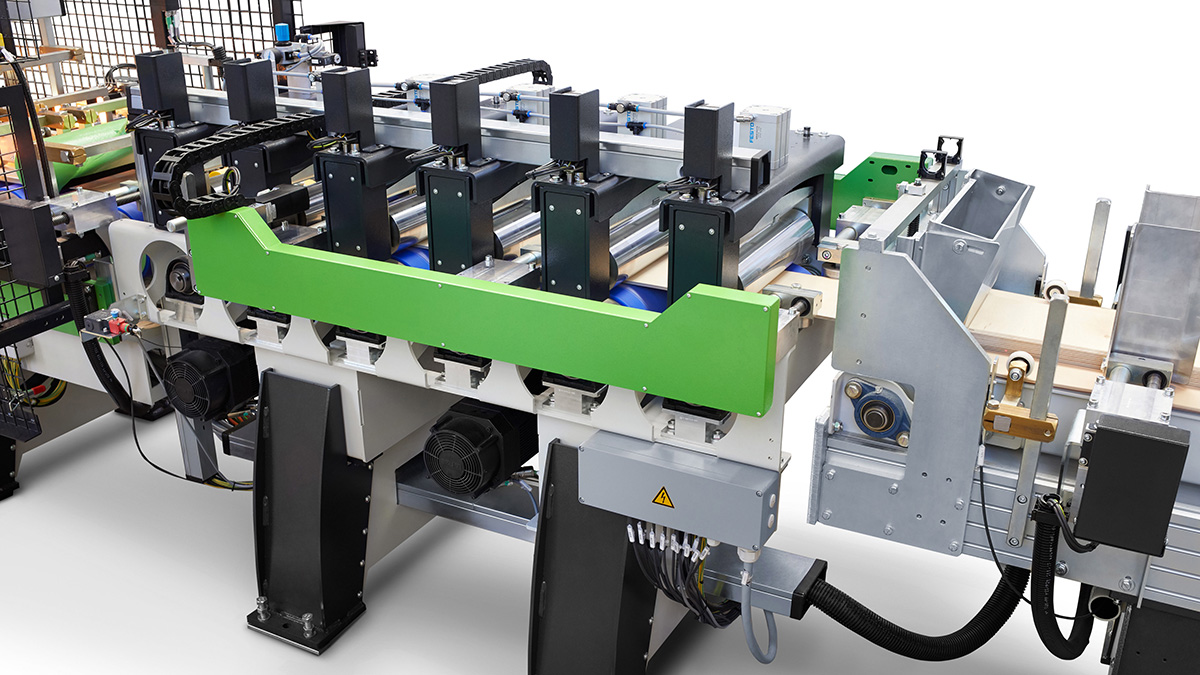

Pressing zone

XPress performs at up to 100 m/min

Infeed section

XPress processes base material of different lenghts so you can always purchase the least costly work pieces

Infeed belt magazine & UniMelt

XPress Parquet processes PUR hot melt glue which consists 0f 100% solid components

Highlights

-

Applies PUR adhesive with 100% solid content

-

Pressed boards keep their shape

-

Further production steps trouble-free

-

Easy to place for final customers

-

Significant increase of the out-put (up to 300%)

-

30% of the investment volume that similar automated solutions require

-

Requires little space

References

Klaus Bauer - Scheucher