PVC lamination machine: all the advantages

A PVC (PolyVinyl Chloride) lamination machine foils PVC profiles with an appropriate surface material, mostly PVC foil, by applying hot melt glue to the foil and pressing the foil to the workpiece following its geometry. In this article, you will find out all you need to know about these machines.

Laminate PVC: applications and results

The most common application of laminated PVC profiles are window and door frames. Due to the trend towards more and more individualisation, home owners are not always content with mere white window frames, they prefer coloured windows and doors. Applying PVC foil in different colours, or even wood patterns, enhances the esthetics of buildings.

Another positive side effect is that laminated PVC profiles are more resistant to wear and tear due to UV rays and other influences.

All the benefits of a PVC lamination machine

A PVC lamination machine enables window or system manufacturers to offer window and door profiles in different colours or with natural patterns and improved resistance. If they extrude their own profiles, they can integrate the PVC lamination machine in the line and benefit from the warmth created in the extrusion process.

In order to benefit from a PVC lamination machine, it is important to invest in a line that requires low set-up times. Also, it should be equipped with components to optimise process safety and guarantee high quality, reproducible results. Semi-automated or automated components help to save and restore approved settings quickly and exactly.

The Duespohl’s innovations for PVC

Duespohl has developed and optimised several types of PVC lamination machines. All of them combine a high quality standard equipment with a large choice of proven optional components to reduce set-up times, improve process safety and simplify the operation.

Users also benefit from the fact that Duespohl produces all components of the PVC lamination machine, including premelter and slot nozzle. Additionally, Duespohl is the only manufacturer of a proven primer vacuum application system that requires low set-up times (> 1 minute) and is especially suitable for low VOC primers.

EasyWrap Window

EasyWrap Window is a lamination machine for occasional profile wrapping jobs or a limited number of profile geometries. It can be equipped with most components including the web edge control to keep the foil’s position constant and the foil heating system that improves process safety and reduces glue consumption.

MultiWrap Window

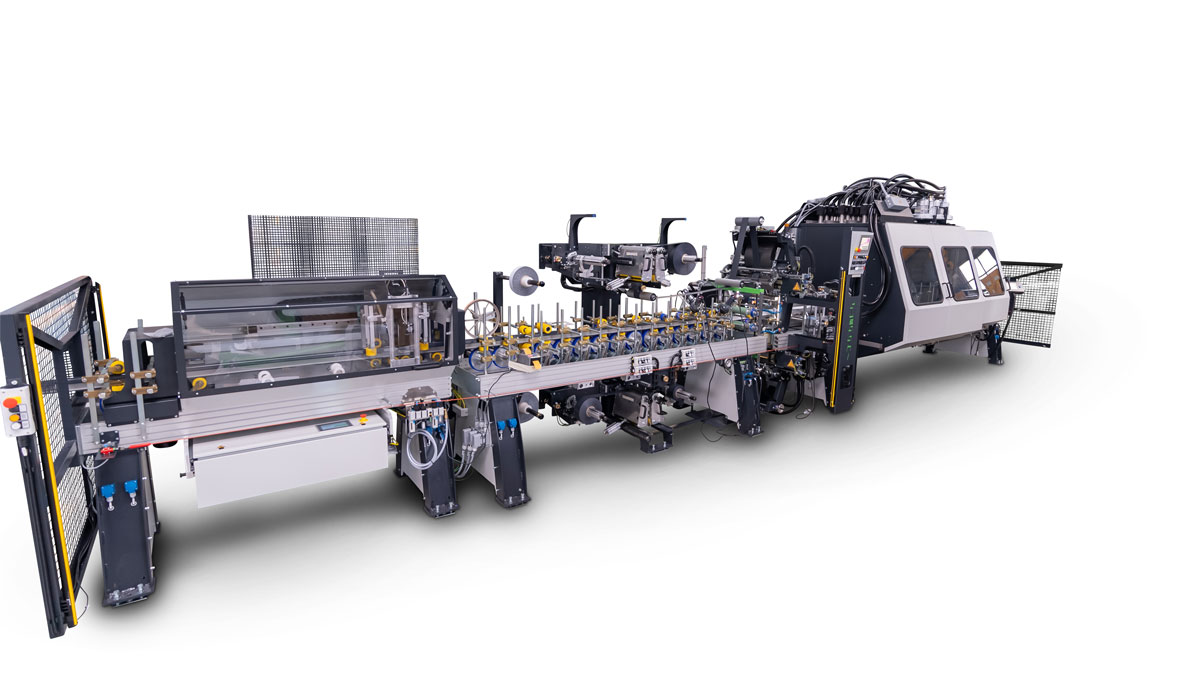

MultiWrap Window is a PVC lamination machine with many configuration options including semi-automated and automated solutions. As an example, the automated format adjustment makes the settings of guidings, set-up aid, transport wheels, pressure roller holders and other components 100% reproducible and reduces set-up times significantly.

(photo shows configuration for inline application)

RoboWrap Window

RoboWrap Window is a maximally automated PVC lamination machine featuring robots which position the pressure rollers in the wrapping zone. The software, which gets smarter every day, even considers the wear and tear of pressure rollers that alter their shape and thus the wrapping results.

All lines can be completed by double unwinding systems to reduce downtimes or an automatic separating system to face skills shortage.

Investing in a PVC lamination line for your business

If you already own a PVC lamination line and add an additional one, you will increase your production capacities and sales volume. Investing in your very first PVC lamination machine, allows you to enlarge your product range by adding laminated PVC profiles with new colours, patterns and enhanced qualities. Of course, working your own PVC lamination line, you will be more independent and able to provide replacements or urgent orders faster, which is a decisive competitive advantage.

When working on the project and choosing the appropriate PVC lamination machine, we recommend to closely consider maintenance efforts, set-up times and availability. A higher investment volume which includes options to reproduce settings quickly and ensure constant quality might pay off faster than you think. Additionally, we advise you to consider the challenge of skills shortage which makes automated solutions in PVC lamination lines even more attractive.