MultiWrap Window

MultiWrap is a real all-rounder in profile wrapping which offers you a wide variety of configurations.

Your individual machine configuration is always based on the requirements of your specific project.

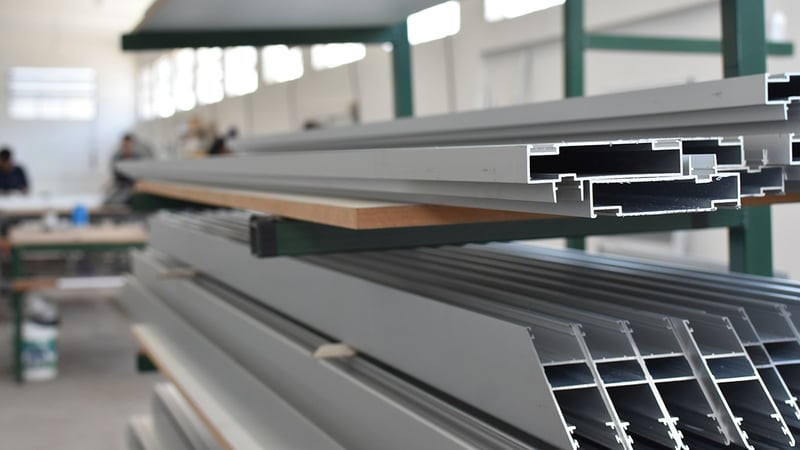

Ideal for

- Window profiles

- Window sills

- Other PVC profiles

- Profiles made from metal

Would you like to receive a free consultation to find out if MultiWrap Window is the solution you need?

Contact us for a non-binding, first conversation.

Description

Different working widths of up to 1000 mm are available.

Our large selection of premelters and the efficient primer application system PrimeStar also make production speeds of up to 40 m per min possible for larger profile sections.

The standard equipment on this series of machines includes:

-

The maintenance-free, infinitely adjustable wide slot nozzle (Duespohl exclusive)

-

Speed and width-related dosing control (glue)

-

Powerful and efficient primer application systems: PrimeStar and DigiApp

-

Energy efficient premelter

-

Automatic tension control

-

Lateral guides with parallel adjustment in the infeed

-

Pressure rollers with tool-free quick-change system

-

Quick-change cassettes in the wrapping zone

-

Transport wheel with tool-free fixing

The optional equipment on this series of machines includes:

-

Automatic slot nozzle positioning

-

Foil heating system

-

Air humidifier

-

Automatic web edge control

-

Automatic reel changer

-

Protective foil unwinding unit

-

Central width adjustment for transport wheels and/or sets of pressure rollers

-

Synchronised separating systems

-

Process data logger with visualisation on touch screen

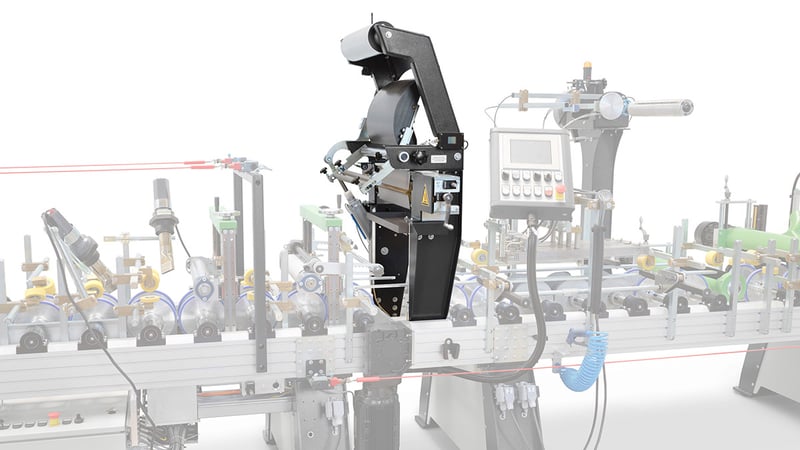

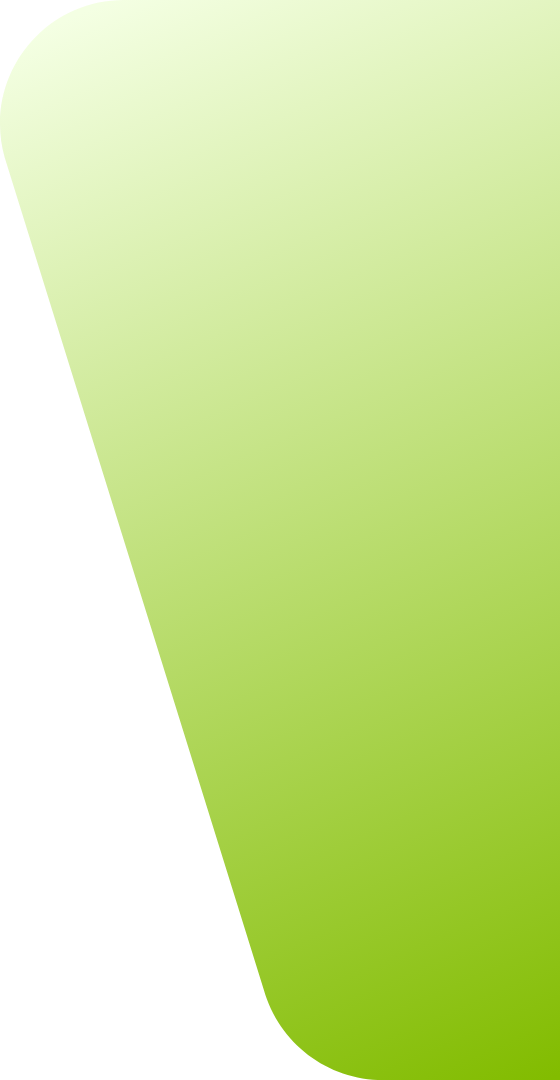

Configuration for inline application

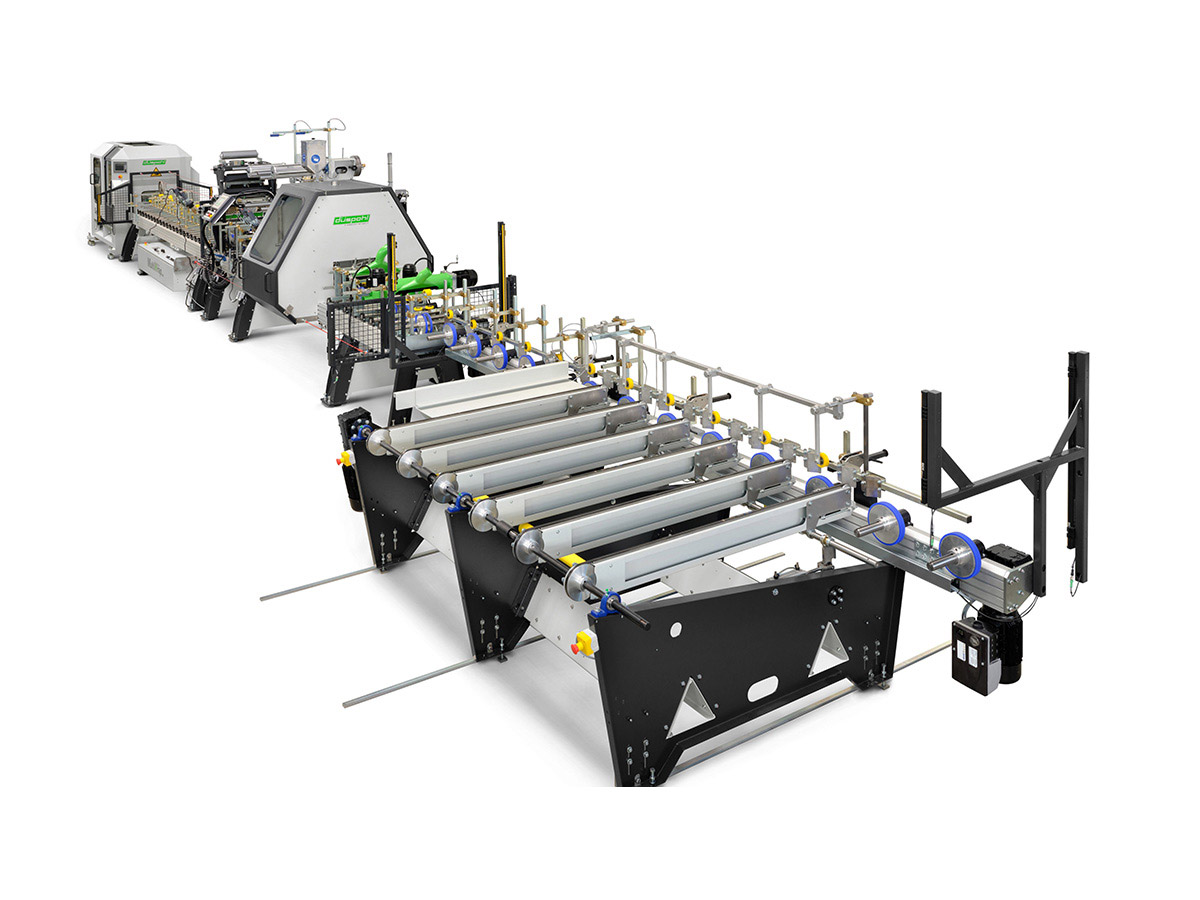

Example of a configuration of a MultiWrap Window for inline wrapping of extruded PVC profiles. Features UniMelt 40, PrimeStar, single unwinding station and foil heating system.

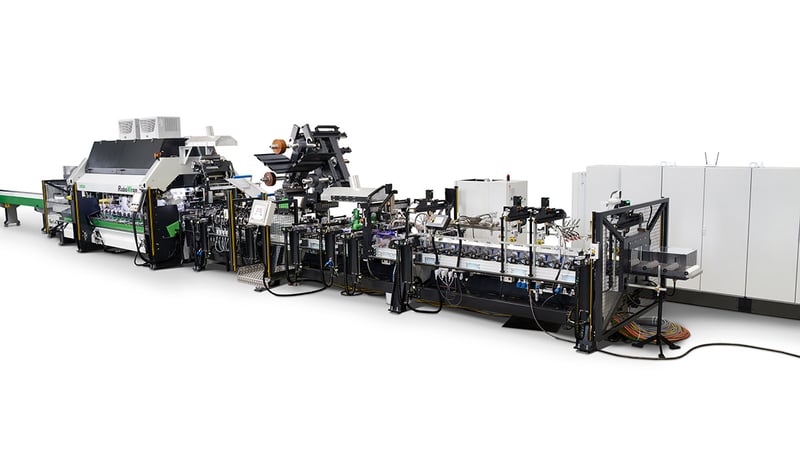

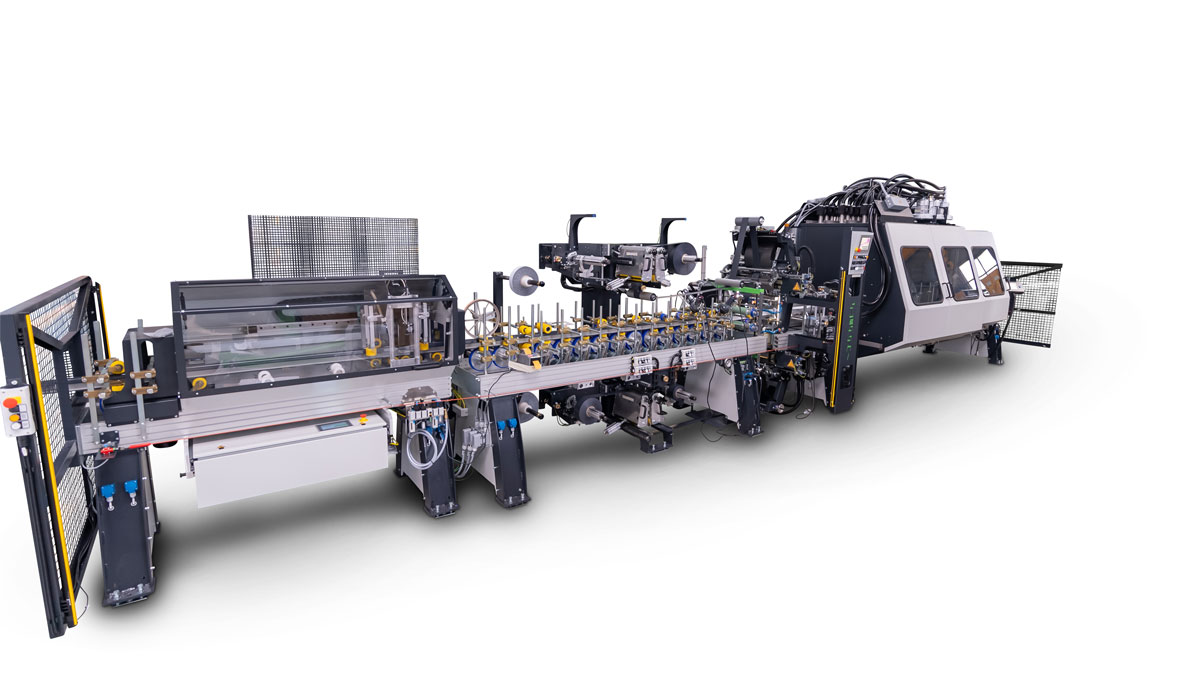

Possible configuration for offline application

MultiWrap Window featuring Crossbelt, simple primer application, double unwinding station, foil heating system and SynCut 220.

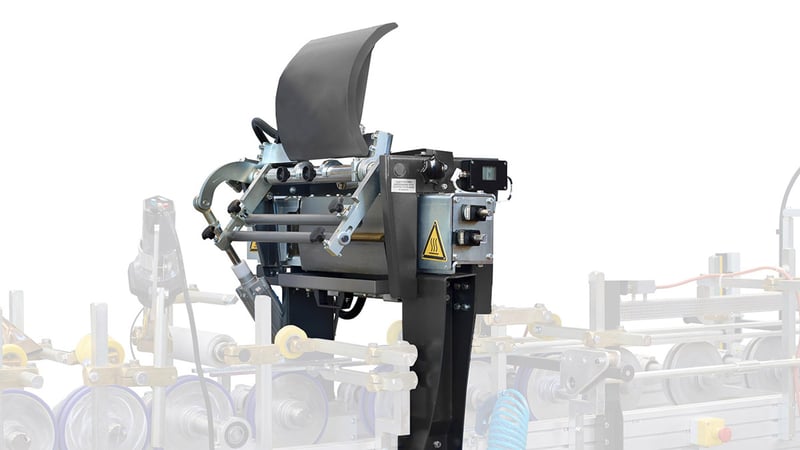

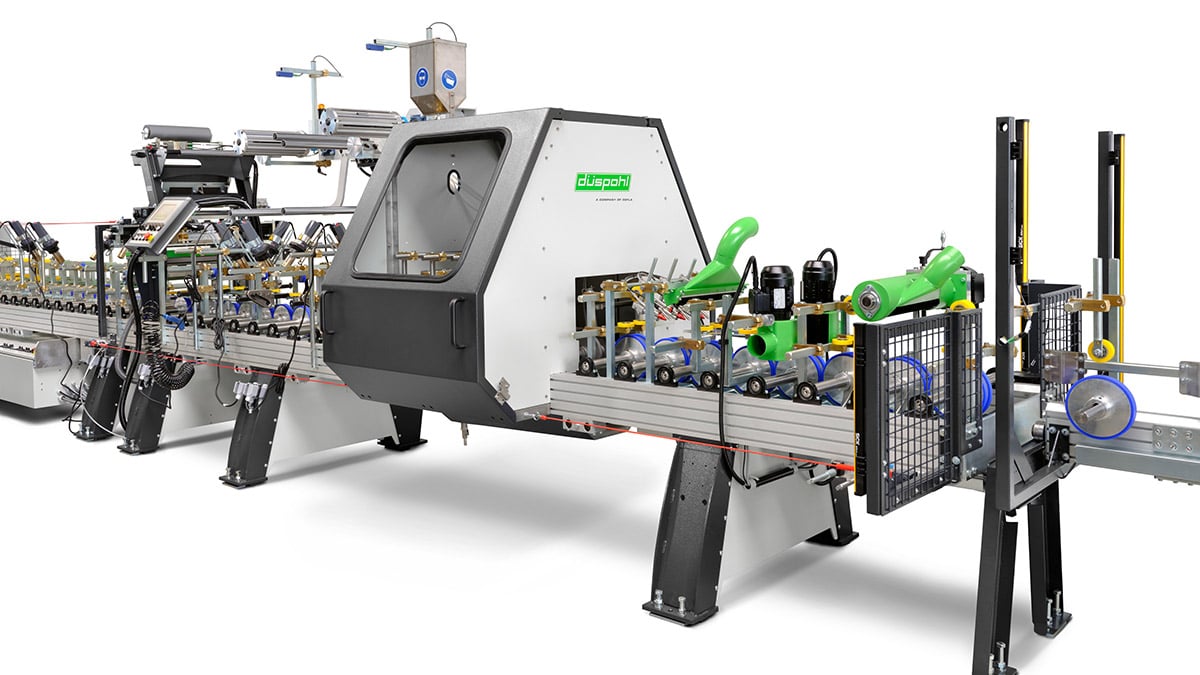

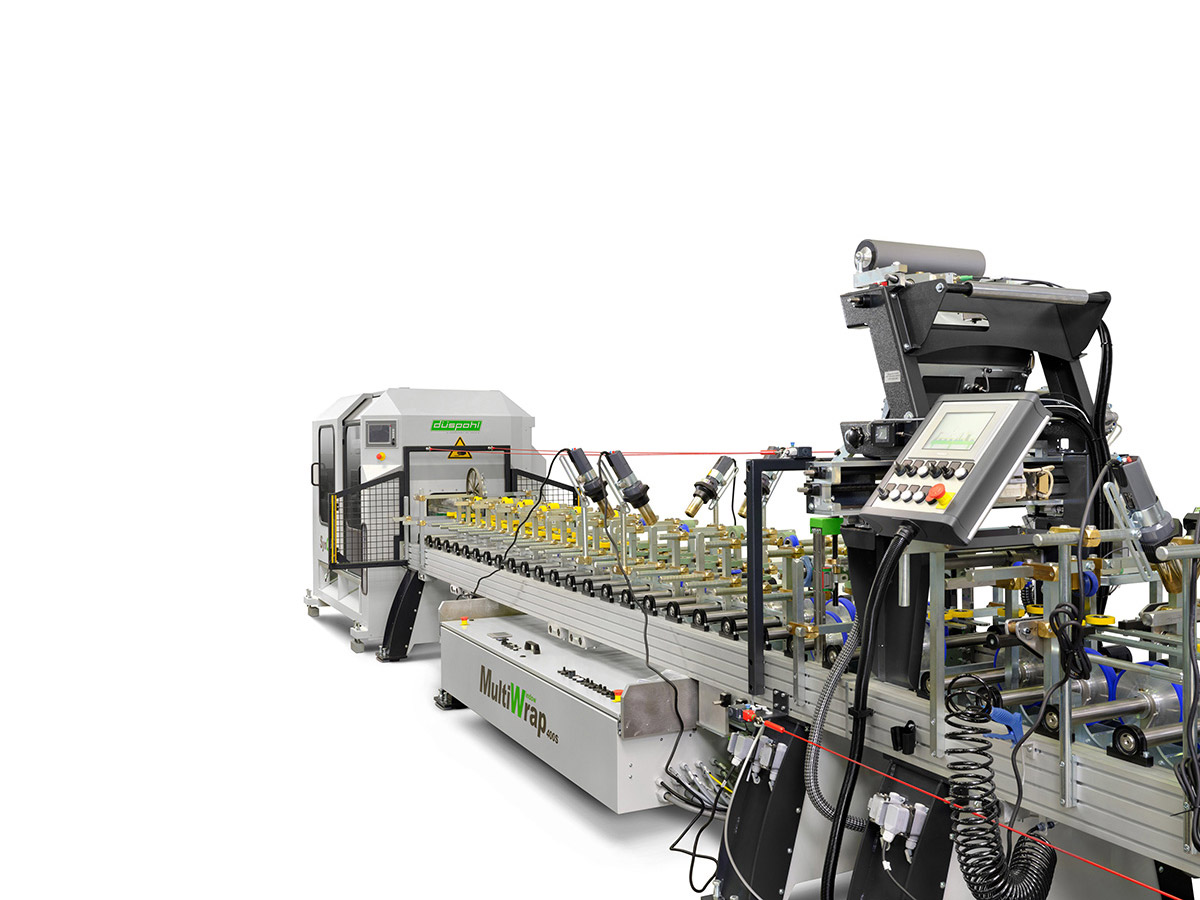

Extract: from glue application to SynCut

Extract of MultiWrap Window 400S featuring Touch Panel, electrical cabinet under wrapping zone and SynCut

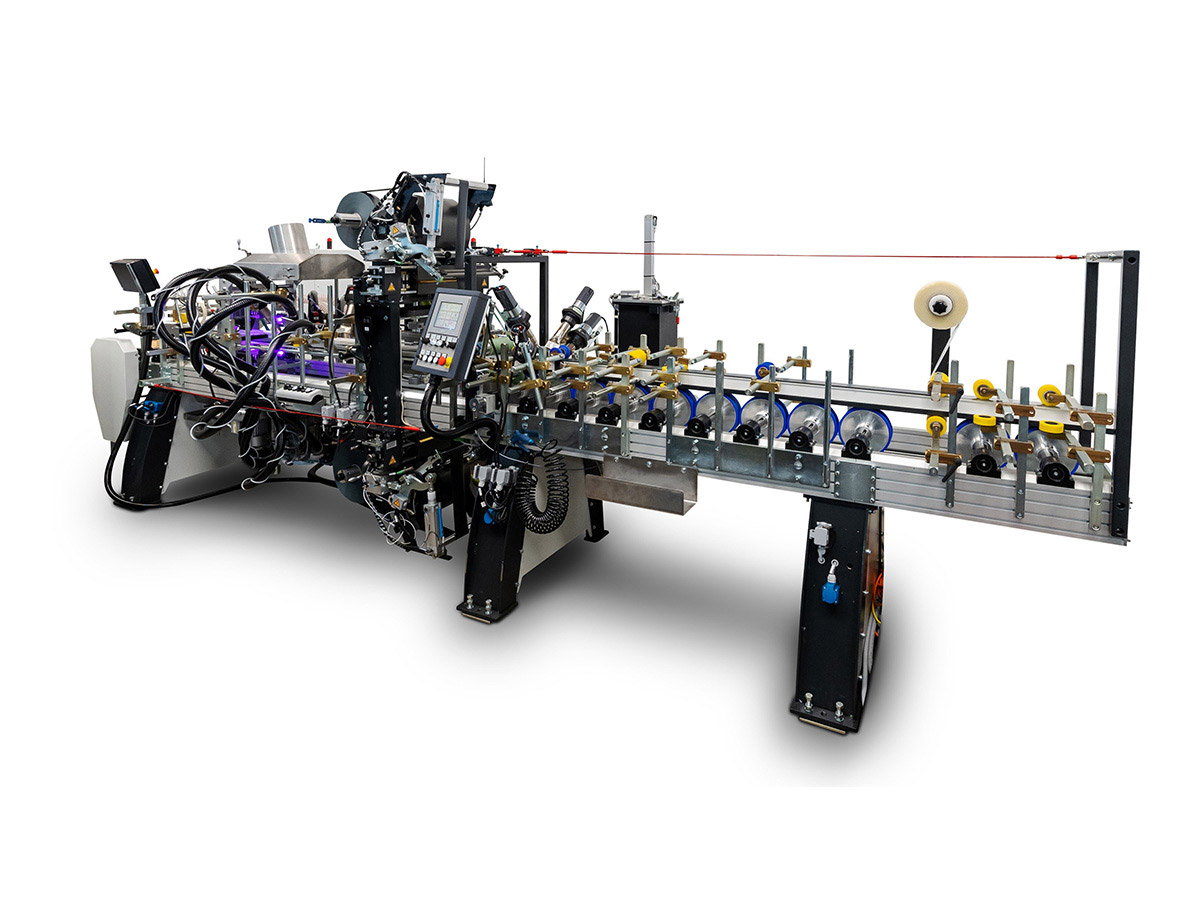

Compact configuration of MultiWrap Window

This MultiWrap Window features a double unwinding station, UniMelt 40 and an electrical cabinet under the wrapping zone

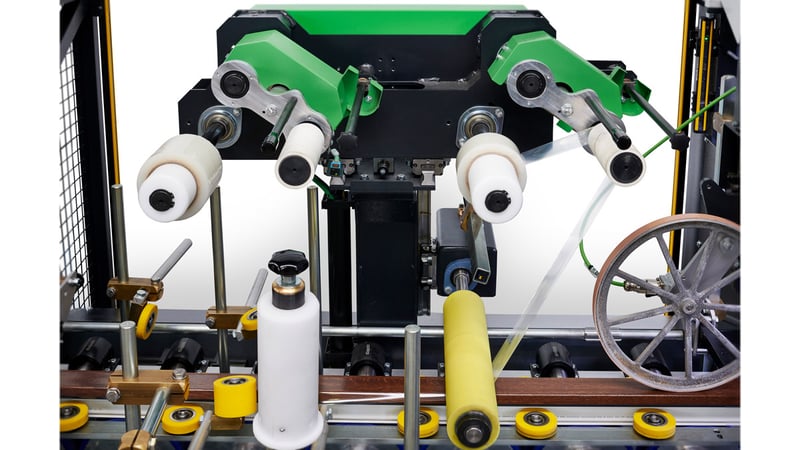

Close Up wrapping zone

Wrapping zone of MultiWrap Window performing simultaneous foiling of top and bottom

Configuration for offline lamination of both sides

This configuration of MultiWrap Window features a foil heating system, Slot Coater, UniMelt, ReelChange Window and SynCut 150G. It wraps top and bottom of PVC profiles simultaneously.

Highlights

-

For inline and offline applications

-

Automatic format adjustment for fast set-up and exact reproducibility of the positions

-

Also for simultaneous foiling of top and bottom

-

Vacuum application system PrimeStar

Downloads

Adam Jaworecki - Trim-Tex Inc.

Nigel Coombes - Homeline UK

Duespohl equipment has proved to be very reliable and has enabled us to meet and sometimes exceed our customer demands. The DigiApp has enabled us to accurately apply low VOC primer to our products which has both economic and environmental benefits. MulitiWrap is extremely user friendly enabling quick product change overs.