IWF 2022

August 23 - 26

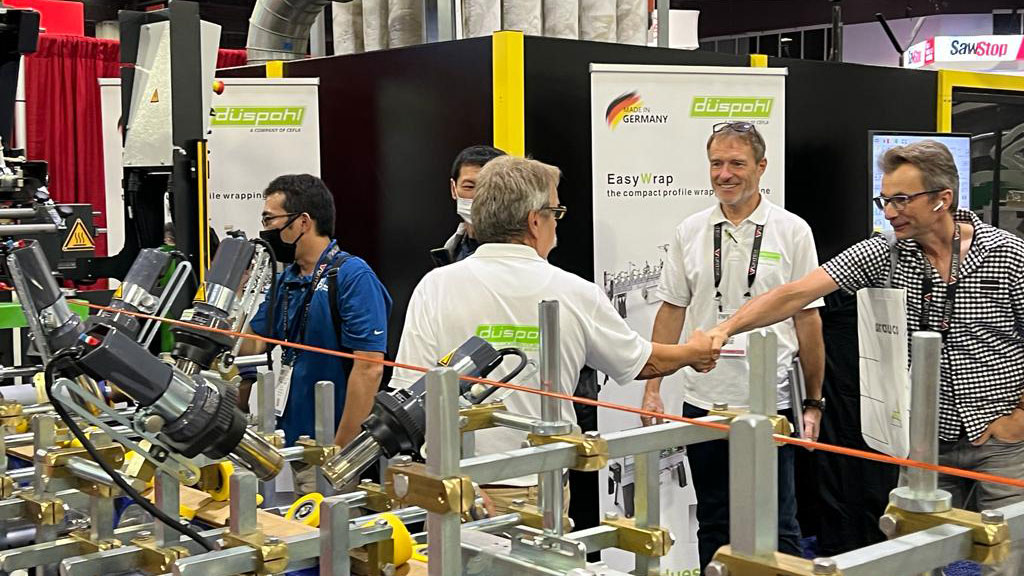

It was great to meet you!

Looking forward to IWF 2024.

A great show

We really had a great time in Atlanta, meeting many interesting people and having many expert conversations on profile wrapping and laminating.

Visitors were especially interested in automated solutions, like the SynCut 150B, because skilled staff is harder to find. Also, we are especially proud that one customers confirmed that we did not delivery "only machinery, but solutions" to help him run his business.

Many thanks to the entire IWF team! Looking forward to the next time.

Find out how to boost your productivity

We were so happy to be back in Atlanta at IWF 2022 for an in-person event - and we did not come empty handed. To make sure your visit to our booth would pay off, we showed you some great automation solutions that reduce set-up times, ensure high product quality and reduce the need of skilled staff - which gets harder to find every month.

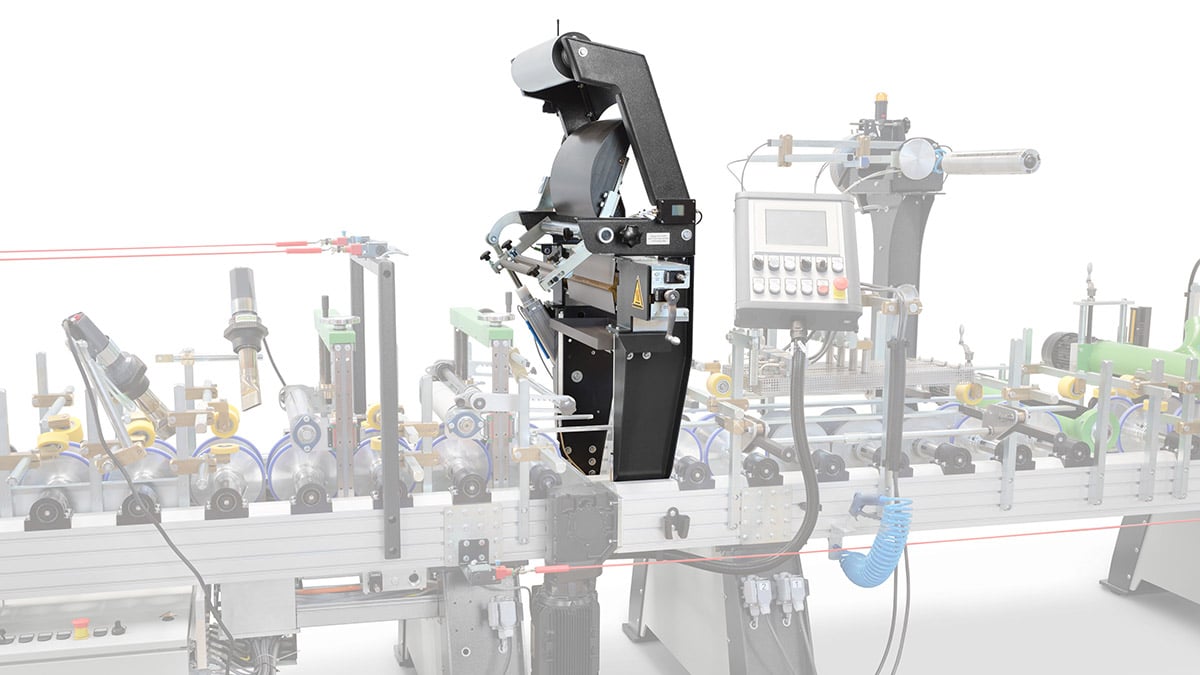

To celebrate the real life meeting, we brought a real, tangible profile wrapping machine including a dynamic cutting unit that enables you to produce at impressive speeds.

What are the line and components we exhibited at IWF 2022?

MultiWrap Wood

MultiWrap is a real all-rounder in profile wrapping which offers you a wide variety of configurations.

Your individual configuration of this profile wrapping machine for wood (composites) is always based on the requirements of your specific project.

Ideal for

- Plinth panels & skirting boards

- Profiles for door frames

- Picture frames

- Other profiles made from wood (composites)

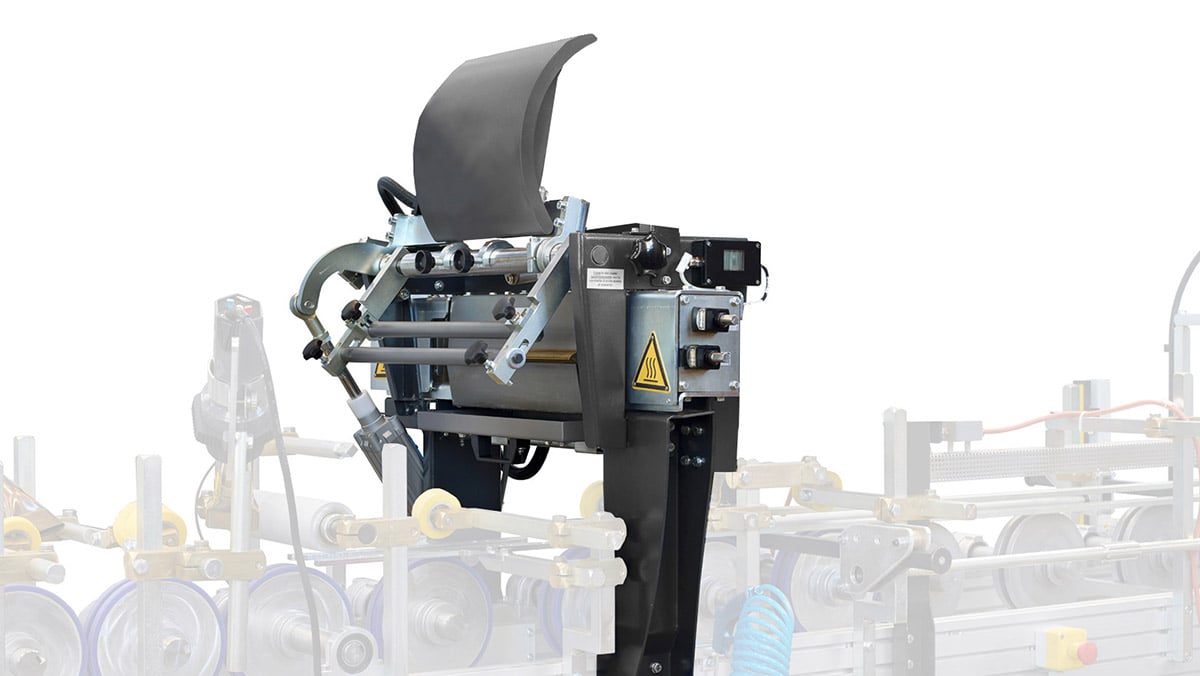

UniMelt

UniMelt can be used for all common adhesive applications; doctor blades, adhesive rollers and slot coaters. It works with EVA and PUR hot melt adhesives and processes all commercially available adhesive blocks from 2 - 20 kg or granulates.Ideal for

- EVA

- PUR

SlotCoater

The internationally successful slot coater by Duespohl is available for glue application widths from 250 to 1400 and works with all surface materials on reels.Ideal for

- all profile wrapping lines processing surface material on reels

Foil-Heating-System FHS

The Foil-Heating-System FHS heats wrapping material to a pre-selected temperature, independently from the temperature that it has before.Using this unit, you increase the process safety and surface quality of the wrapped profiles.

Ideal for

- all profile wrapping lines

- all laminating lines

Double unwinding station

The double unwinding station with manual change of surface material allows you to switch from one decorative material to another without interrupting the production. It works with the common wrapping materials and is equipped with the tension control system, just like the single unwinding station.Ideal for

- EasyWrap Wood

- MultiWrap Wood

- EasyWrap Window

- MultiWrap Window

- offline applications

SynCut 150B

SynCut 150B is a synchronized flying cut-off saw to separate profiles while in motion. Its operating mode combines high dynamics with low tolerances. It works independently from the precedent machine and delivers high quality cutting results thanks to its unique design.Ideal for

- Plinth panels & skirting boards

- Picture frames

- Other profiles made from wood (composites)

Catalog request

Would you like to have a look at Duespohl's products for the wrapping of wood and wood composite profiles?

References

Adam Jaworecki - Trim-Tex Inc.

References

Oscar Taboas - Royo

References

Duespohl equipment has proved to be very reliable and has enabled us to meet and sometimes exceed our customer demands. The DigiApp has enabled us to accurately apply low VOC primer to our products which has both economic and environmental benefits. MulitiWrap is extremely user friendly enabling quick product change overs.

Nigel Coombes - Homeline UK

References

Pal Endre - SET Prod-Com

References

Andrew Tweddle - BHK UK

Your Sales Manager

If you came to our booth, you probably met Andreas Jaeger (black T-Shirt), our US Sales Manager with more than 30 years of experience in the woodworking sector.

He travels to the US regularly and will be happy to help you to improve your process and product quality.