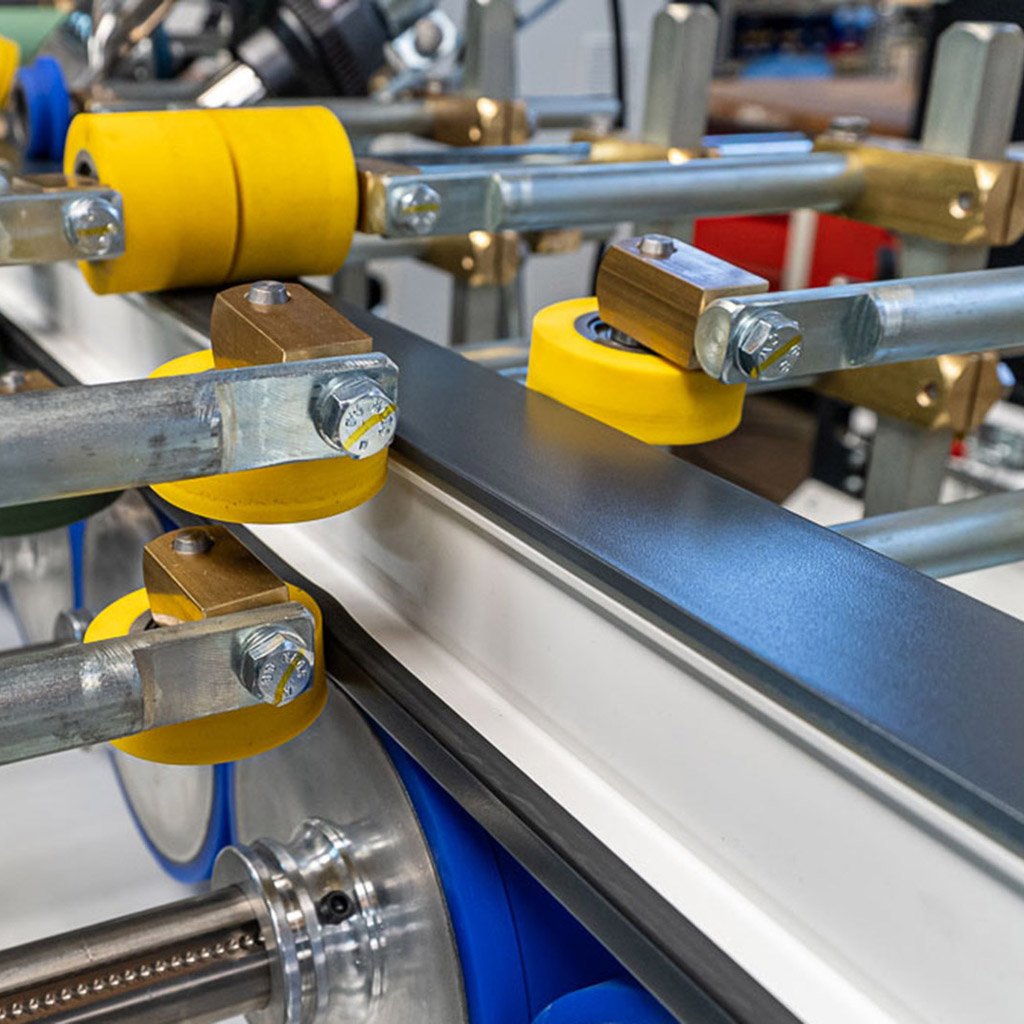

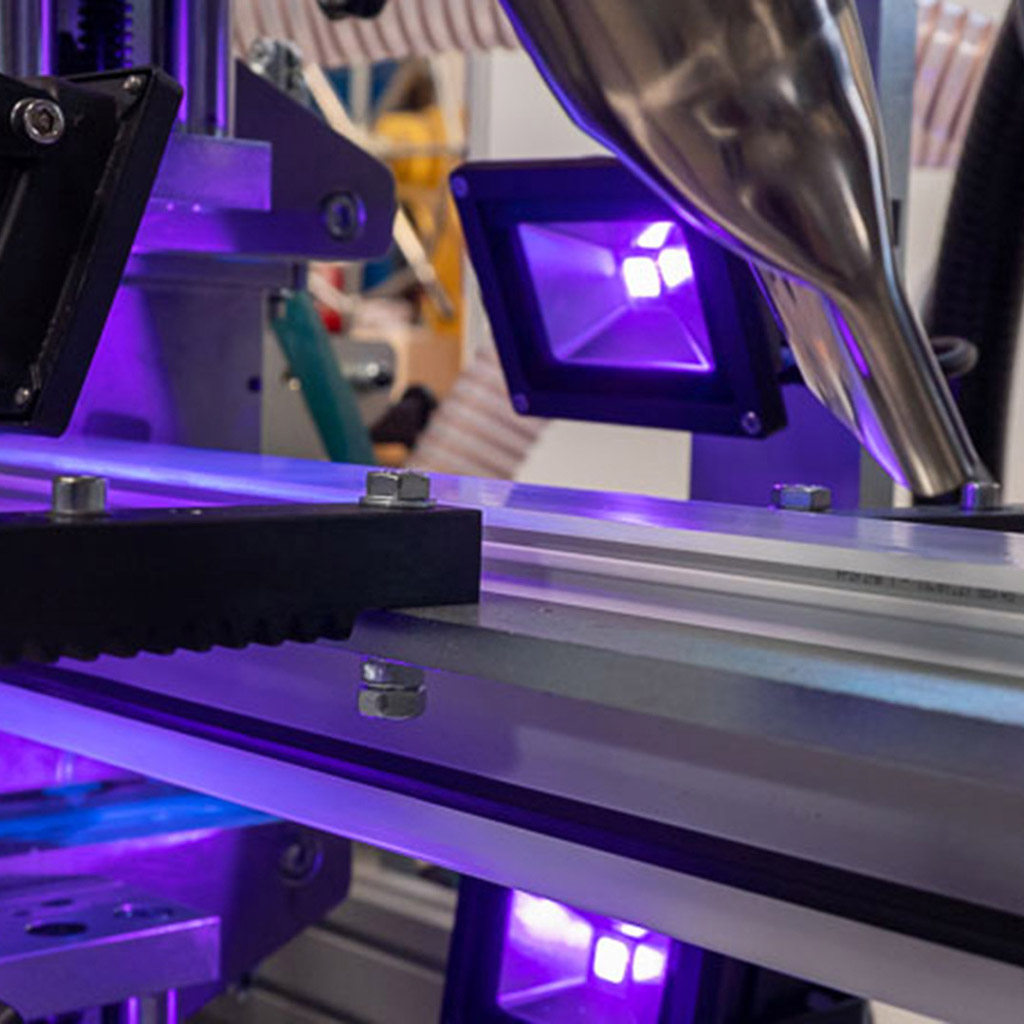

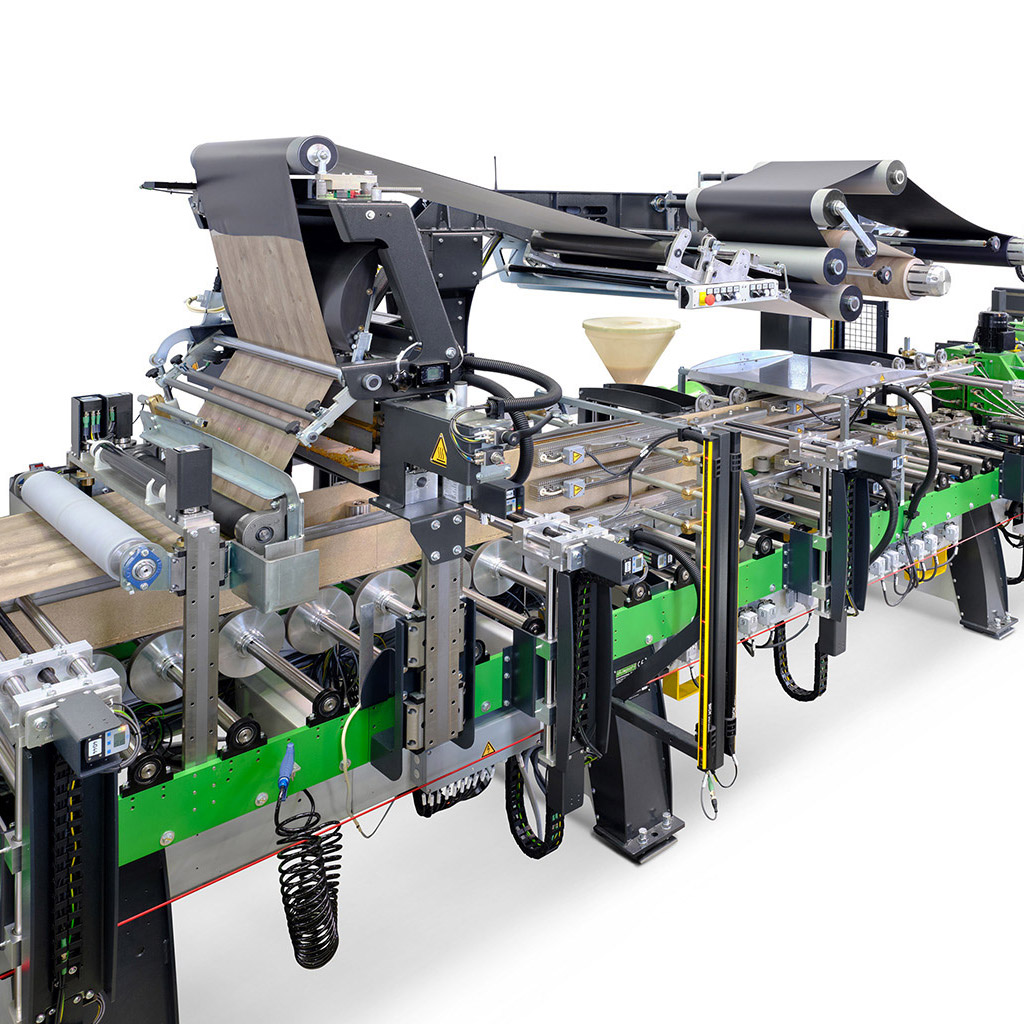

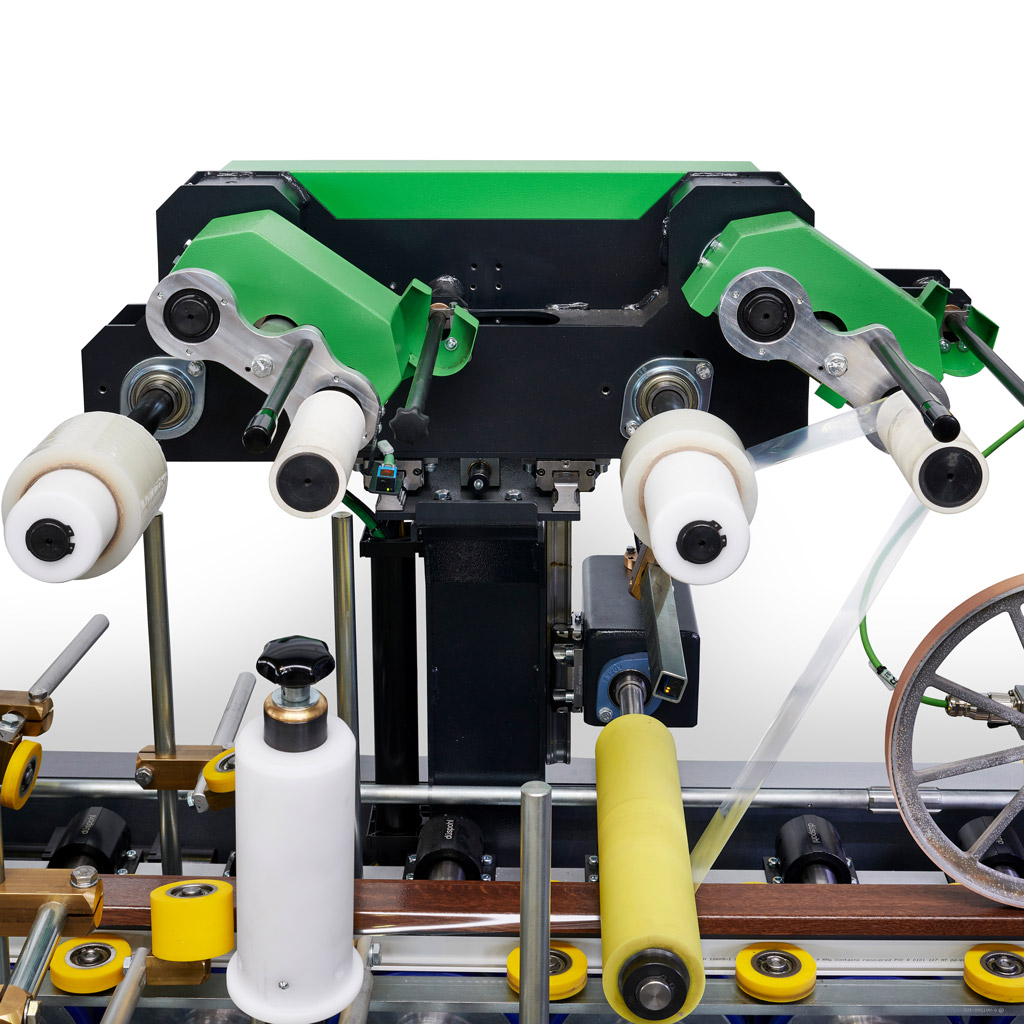

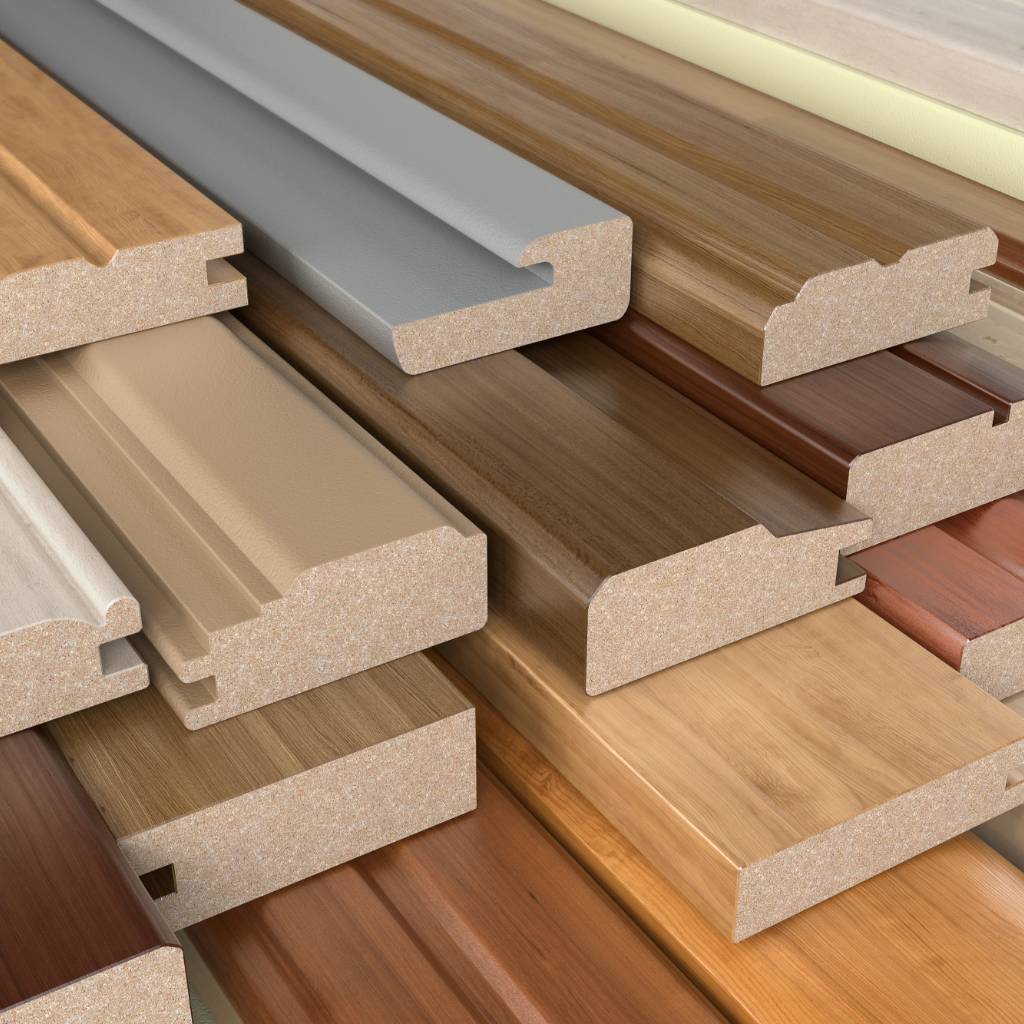

Development and

manufacturing of

profile wrapping

and laminating lines

Our products

Our applications

Beware of fraud

Unfortunately, some companies have received fraud emails, pretending to be order by Duespohl. These emails have been sent by adresses ending on "duesspohl.com" (with 2 "s").

If you have received any order that seems suspicious, please contact us so we can confirm it.

News & Events

LIGNA 2023 in Hanover, Germany

Looking forward to meeting you again in Hanover. Do not miss the chance to see smart, productivity...

Conclusion of AI Marketplace project

The scope of the AI Marketplace is to create a central contact point for Artificial Intelligence...

New System ReelScan | Corporate News Düspohl

At LIGNA 2023, Duespohl presented the new system ReelScan that simplifies the identification of the...

FastChange - for a quicker set-up | Corporate News Düspohl

Changing from one profile geometry to another is one of the most time consuming challenges in...

Come to Glassbuild in Orlando, USA!

We’re bringing innovation in wrapping to the leading industry trade show in North America: ...

.jpg)

Come to Fensterbau Frontale in Nuremberg: Düspohl is waiting for you

Düspohl at FENSTERBAU FRONTALE 2026

Who’s Duespohl

Duespohl develops and manufactures profile wrapping lines, laminating lines including all components and related machines like slitting machines and parquet presses.

References

Torsten Fidyka - Profine Group

References

Oscar Taboas - Royo

References

Duespohl equipment has proved to be very reliable and has enabled us to meet and sometimes exceed our customer demands. The DigiApp has enabled us to accurately apply low VOC primer to our products which has both economic and environmental benefits. MulitiWrap is extremely user friendly enabling quick product change overs.

Nigel Coombes - Homeline UK

References

We work with the machine (EasyWrap Window) every day and are very happy with its performance and functionality. Operating the line is easy and uncomplicated, which helps us save time and optimise the working process. Also, the quality of the wrapped products is impeccable and corresponds to our high standards.

A further advantage is the higher production flexibility. We can easily adapt the machine to the needs and requirements of our customers to fulfill individual wishes. At the same time, foiling our own window profiles gives us more control of the entire production process. This results in higher quality and minimises wastage.

We would like to especially point out Duespohl's customers service. Whenever there is a question or problems, the employees are always available, friendly and competent.

Pascal Flesch - Franz Jäger GmbH

References

Adam Jaworecki - Trim-Tex Inc.