MultiWrap Wide

Ideal for

- Window sills

- Pannelling

- Doors for furniture and kitchen cabinets

- Panels and boards, wood & PVC

- Furniture bodies

Would you like to receive a free consultation to find out if MultiWrap Wide is the solution you need?

Contact us for a non-binding, first conversation.

Description

Equipped with a combination of laminating and wrapping zone, MultiWrap Wide laminates boards and their edges in one single pass. It also features many systems to reduce set-up times and increase your output.

MultiWrap Wide uses hot melt adhesive to glue the surface material to the panels which means that the laminated boards will immediately be ready for further processing. Consisting of 100% solid material, hot melt glue has another great advantage: the panels will not be deteriorated by orange peel.

The standard equipment on this series of machines includes:

-

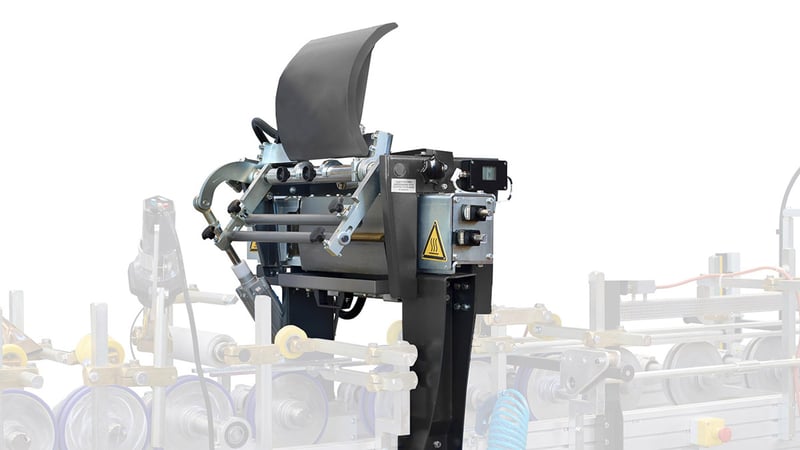

Internationally renowned Slot Coater

-

Quick adjustment of transport wheels

-

Tool-less quick fix system of pressure rollers

-

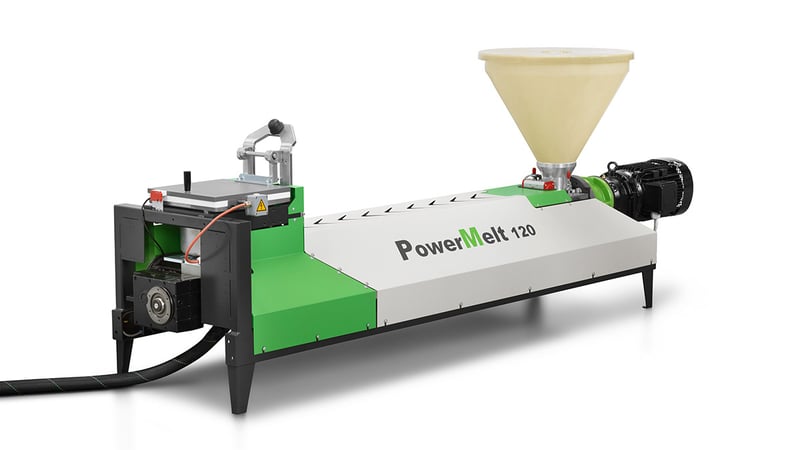

High performance premelter

The optional equipment on this series of machines includes:

-

Web edge control

-

Slot Coater positioning

-

Foil heating system

-

Automatic reel change system

-

Diagonal saw

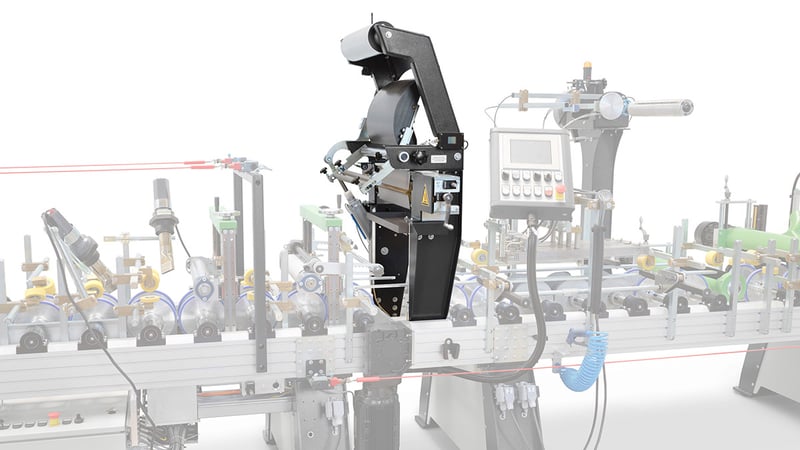

Focus on saw and trimming station

MultiWrap Wide 700S opens it doors to show us the trimming station and the diagonal saw SynCut 700

MultiWrap Wide 700

This laminating lines features UniMelt 80, SlotCoater, single unwinding station, a trimming unit and the diagonal saw SynCut 700. The electrical cabinet has been placed below the wrapping zone.

Highlights

-

Laminating and wrapping of edges in one pass

-

Different laminating rollers for different qualities of work pieces

-

All parts from Duespohl manufacturing incl. premelter and diagonal saw

-

Reduced set-up times, low maintenance efforts