PowerWrap Wide

Ideal for

- Pannelling

- Doors for furniture and kitchen cabinets

- Panels and boards, wood & PVC

- Furniture bodies

Would you like to receive a free consultation to find out if PowerWrap Wide is the solution you need?

Contact us for a non-binding, first conversation.

Description

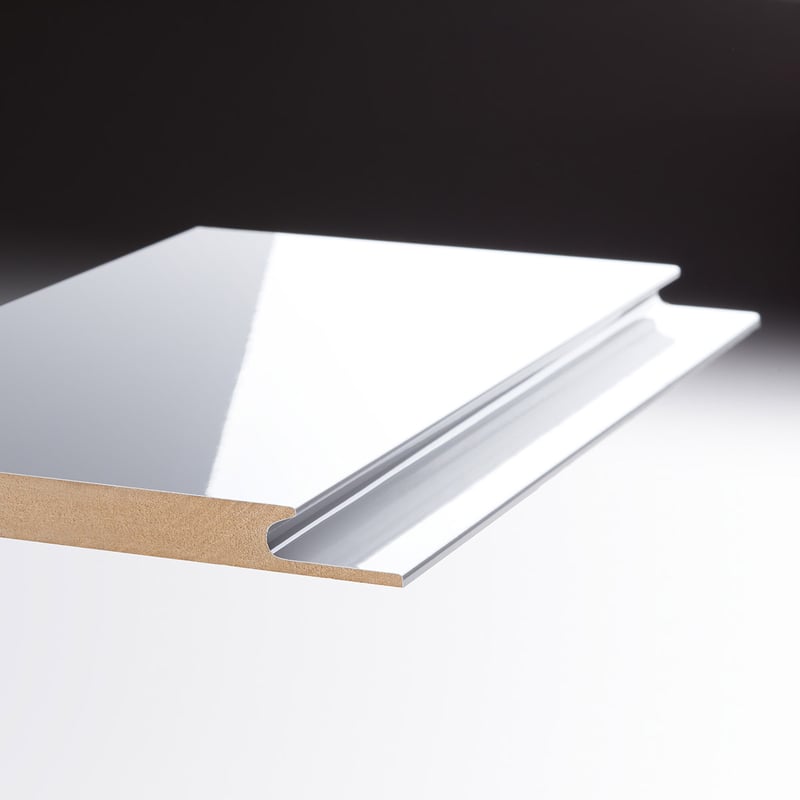

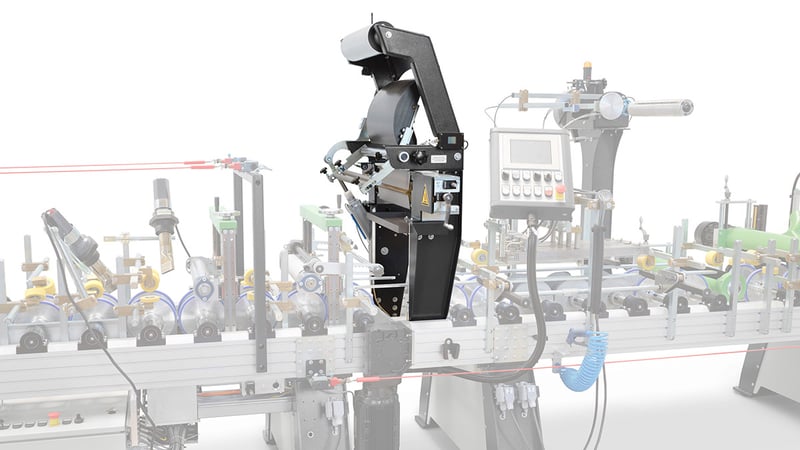

The laminating line PowerWrap Wide is used for laminating flat wood and plastic panels with decorative materials in reel form, up to a working width of 700 mm, 1000 mm or 1400 mm. The glue application takes place with an infinitely adjustable slot nozzle.

This laminating line also processes high-gloss decors and allows a continuous coating of both fronts, as well as the edge area. Not only does the machine deliver optimal coating results, it also works extremely energy efficiently.

The modular design allows the machine to be adjusted according to your individual needs. In addition, the complete adhesive preparation and application equipment as well as separation systems are also available from our own production.

The direct application of the molten adhesive to the decorative material in the production process allows the seamless coating of even complex geometries in the edge area such as fronts with recessed grips. Compared to processes that reactivate already cooled adhesive, the integrated glue application system in this machine has decisive energy-efficiency and qualitative advantages, since the required application quantity can be adapted individually.

The standard equipment on this series of machines includes:

-

Maintenance-free, infinitely adjustable wide slot nozzle (Duespohl exclusive)

-

Speed and width-related dosing control (glue)

-

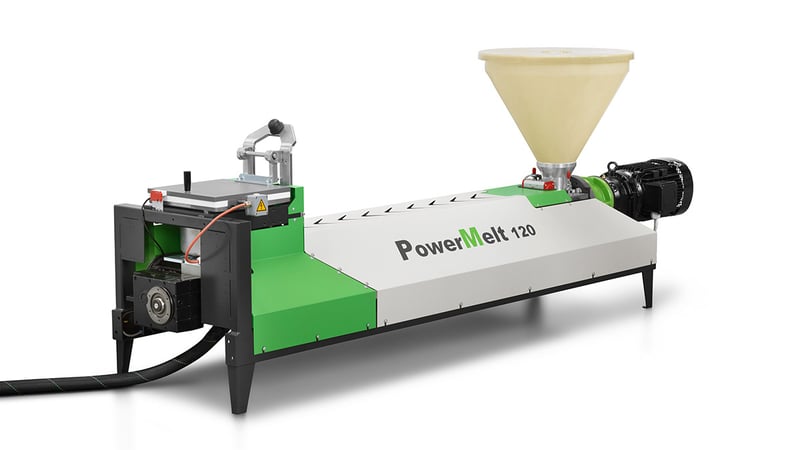

Energy efficient premelters for up to 300 kg/h

-

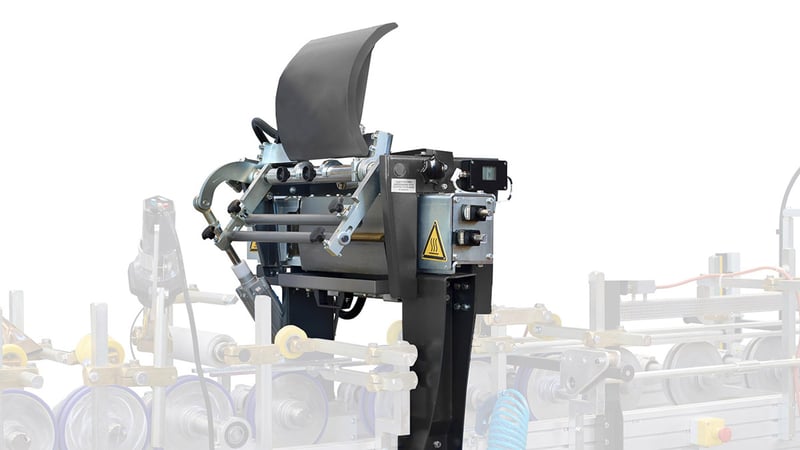

Combinations of different laminating rollers for different material qualities

-

Quick-change cassettes in the wrapping zone

-

Transport wheels with tool-free fixing

The optional equipment on this series of machines includes:

-

Automatic slot nozzle positioning

-

Automatic foil heating system

-

Automatic web edge control

-

Automatic reel changer

-

Milling and trimming units

-

Synchronised diagonal saw

-

Process data logger with visualisation on touch screen

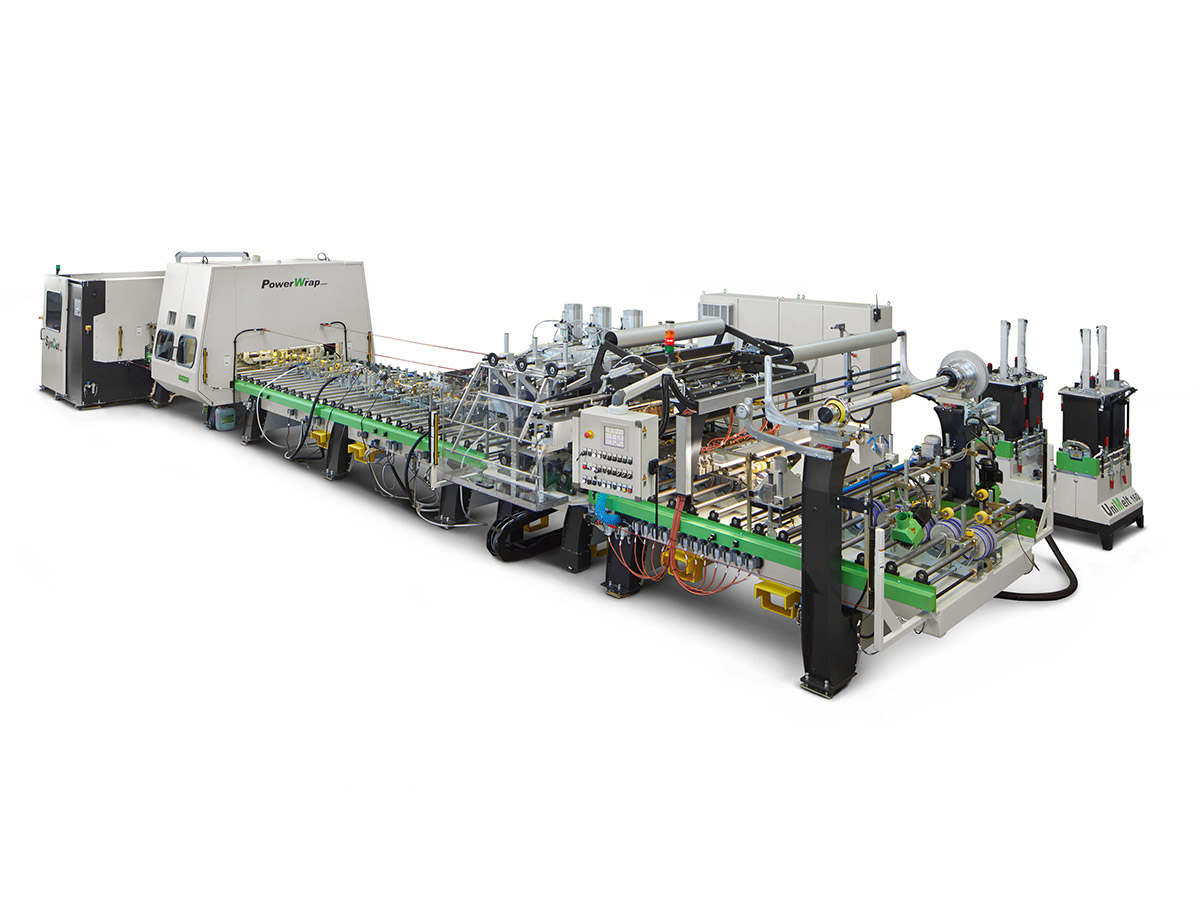

PowerWrap Wide 1400S

Configuration for J-Pull doors with high glossy surfaces, including UniMelt 160, 1400 mm SlotCoater, Foil Heating System, laminating zone with 3 rollers, trimming unit and SynCut 1400

Close-Up

PowerWrap Wide laminates the surface and wraps edges, even J-Pull handles

PowerWrap Wide 1000S

PowerWrap Wide with UniMelt 160, 1000 mm wide Slot Coater, diagonal saw SynCut 1000

Highlights

-

Laminating and wrapping of the edges in one machine

-

Flexible response to workpiece properties through special roll materials and geometries

-

Significant energy savings through integrated pre-melting and adhesive application technology

-

Patented wide-slot nozzle with over 1000 installations worldwide

-

Uninterrupted production if the machine is fitted with an automatic reel changer ReelChange Wood

-

Almost unlimited geometries in the edge area with the surface coating material are possible to process

-

All units, from the adhesive preparation to the running diagonal saw produced in-house

-

Protective foil processing

-

Significantly reduced set-up time through patented systems